Design & Tooling

HX5 thermoplastic nanocomposite demonstrates electromagnetic shielding properties

Certified for use from rockets and satellites to amphibious transport vehicles, EMI testing indicates exceptional attenuation when bare or plated for shielding effectiveness.

Read MoreTalgo announces launch of hydrogen train by 2023

The new system will be configured as a modular solution that can be installed on all types of trains, as well as for upgrading previous diesel versions to hydrogen.

Read MoreClean Sky 2 IMCOLOR project develops integrated manufacturing process for lightweight product design

Multi-shot injection molding process and thermoplastic automated fiber placements with in-situ consolidation for automated, easy-to-reproduce parts that perform at high mechanical levels.

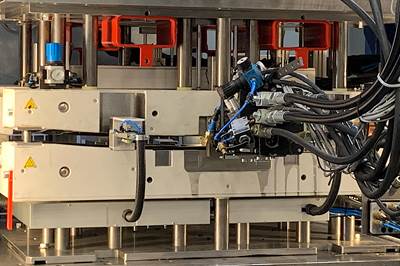

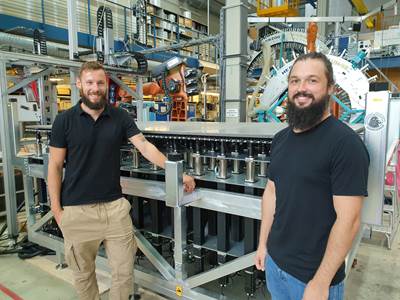

Read MoreCSP fine-tunes CF-RTM process, launches production programs

The carbon fiber RTM press will be installed at the CSP facility in Palmela, Portugal in order to run the company's first commercial applications using this technology.

Read MoreAvions Mauboussin launches STOL hybrid-hydrogen aircraft

Hybrid Zéphyr engine for electric/hydrogen capabilities and a natural fiber composite-based design revive and reinvent an energy-efficient aircraft brand.

Read MoreTestia releases multi-method acquisition system for NDT inspection methods

Multi-method UE1 Box, phased array U32 Box and SKD architecture improve activity efficiency and meets technical specifications on a flexible, cost-effective platform.

Read MoreCFP Composites launches low-cost, carbon fiber laminate that processes like metal

The BM-5 laminate board can be screwed, tapped, fastened, bonded and painted just like a metal, and requires no prepreg, layout or curing. It also has a comparable cost to metal, removing operator and financial barriers to adopt carbon fiber.

WatchComposites mold manufacturer, BBG, is finalist for Germany’s best toolmaker 2020

Smart molds for Industry 4.0 applications key to its recognition in “Excellence in Production” competition.

Read MoreUniversity of Stuttgart, Institute of Aircraft Design uses adaptive mold technology from Adapa

Reconfigurable mold aids development of digitally-manufactured composite parts for reduced-emissions transport vehicles.

WatchSkoltech optimizes pultrusion process productivity

The institute analyzed the influence of pulling speed on the structural characteristics of L-shaped profiles, analyzing the interconnection between a variety of characteristics.

Read More