Fabrics/Preforms

CAMX 2016 Show Report

The 3rd annual joint ACMA/SAMPE-sponsored trade event comes to Anaheim with an exhibition and conference program attractive to professionals across the composites world.

Read More3D knitting solves preforming cost, time

Disruptive digitized technology a dramatic step-change in near-net preform production for Dassault Falcon interior air duct.

Read MoreIs the BMW 7 Series the future of autocomposites?

BMW AG's Dingolfing, Germany, auto manufacturing facility is well known for churning out a variety of car models and types, and the 7 Series is among them, famous for its steel/aluminum/composites construction. Does this car represent the optimum of composites use in vehiicles? This plant tour of the Dingolfing plant looks at how composites on the 7 Series come together.

Read MoreSpread-tow fabrics: better than traditional reinforcements in aerospace applications?

There’s a lot happening in the area of spread-tow fabrics, yet aerospace adoption has been slow because of a lack of analytical tools and performance tests, particularly impact tests.

Read MoreMETYX Composites expands Turkey site

The expanded site is almost twice the size of the current factory, providing METYX with the space to double weaving capacity for glass and carbon fiber multiaxial fabrics.

Read MoreGet ready for Composites 4.0!

It might seem like science fiction, but it must be our path if we are to make composites competitive.

Read MoreTaking the hand out of hand layup

Hand layup has a long history in aerospace composites fabrication, but it's not well suited for automotive composites manufacturing, where volumes are much higher. But the discrete placement of fiber reinforcements still has value. Research is pointing toward automated hand layup that might help this process bridge the aerospace-to-automotive divide.

WatchCarver Non-Woven Technologies opens its doors

US-based Carver Non-Woven Technologies offers nonwovens made with glass fiber, bast, carbon fiber, basalt fiber and thermoplastic fibers in densities ranging from 300-2,400 gsm.

Read MoreA&P, TenCate test database compares slit-braid and woven fabric

A&P Technology Inc. (Cincinnati, OH, US) introduced at JEC World 2016 a new database of test data, developed with TenCate Advanced Composites (Morgan Hill, CA, US) to compare laminates composed of its trademarked QISO quasi-isotropic (0°, ±60°) fabric, a slit braid material, with laminates composed of conventional woven fabric, both prepregged with TenCate’s highly toughened TC275-1 epoxy resin.

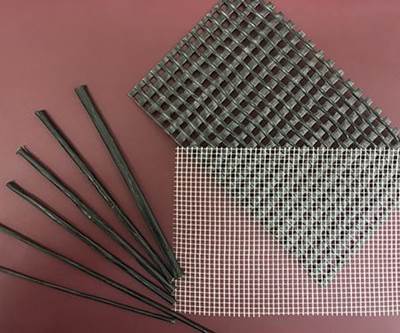

Read MoreSelective reinforcements boost “commodity” composite properties

Strategically placed advanced reinforcements reduce weight, cost while dramatically increasing mechanical performance and dimensional stability.

Read More