Filament Winding

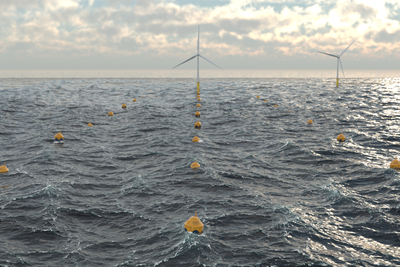

Composites-intensive wave energy technology receives new funding

CorPower Ocean and OPS Composite Solutions secure almost €500,000 from EEA grants to advance buoy-based renewable energy technology.

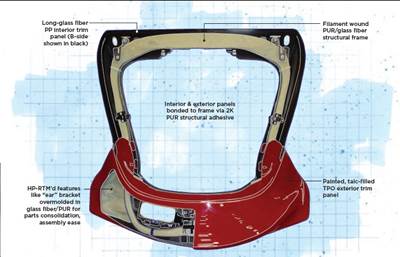

Read MoreLiftgate design puts modified filament winding to the test

Heavily modified winding process produces light, structural support frame for performance-critical liftgate.

Read MoreVirgin Orbit LauncherOne rocket reaches space

Air-launched, liquid-fueled rocket makes historical debut with successfully targeted orbit and 10 NASA NSP payloads deployed.

Read MoreCygnet Texkimp presents next-generation composites unrolling creel

Flatline Creel uses low-pressure, low-friction patented pneumatic technology to regulate the torque applied to each position on the creel.

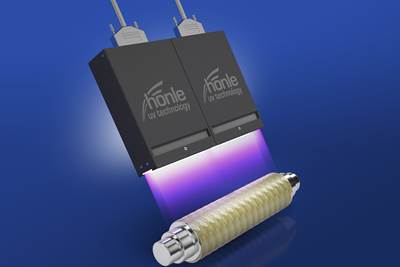

Read MoreTechsil, Panacol offer Vitralit adhesive for filament winding

The transparent one-component epoxy adhesive and curing system is ideal for carbon fiber or glass fiber filament winding.

Read MoreGKN, Raytheon reach agreement for composite missile canisters

Per the three-year contract, GKN Aerospace will provide Raytheon with 95 Mk30 missile canisters that are manufactured via a filament winding process followed by vacuum infusion.

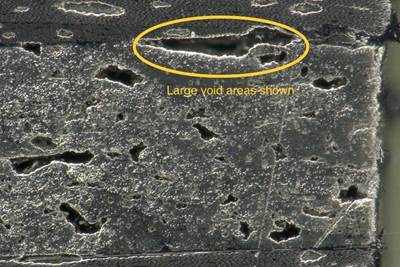

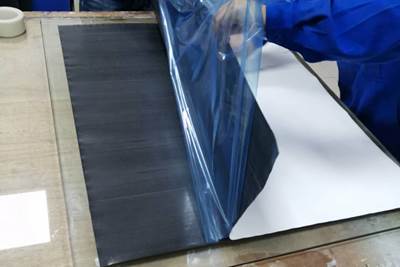

Read MoreRediscovering the benefits of prepregs in composites manufacturing

Compared to more traditional forms of composites manufacturing, prepregs enable reduced manufacturing costs and enhance production performance.

Read MoreSino Polymer develops high-performance epoxy resin systems for prepreg applications

The one-component carbon fiber prepreg can be cured at 150ºC for 10 minutes, is suitable for structural parts requiring Tg within 120-140ºC and can be stored for up to 18 months at -18ºC

Read MoreSino Polymer develops high-performance epoxy resin prepreg

Used in railway applications, the carbon fiber prepreg can be cured at 150℃ for 10 minutes, and is suitable for structural parts requiring Tg within 120-140℃.

Read MoreEngineering Technology launches servo tensioner for filament winding

The ST2 system, tested with pitch carbon fiber and alumina fiber, enables high-speed wet, dry and towpreg winding.

Read More

.jpg;maxWidth=300;quality=90)