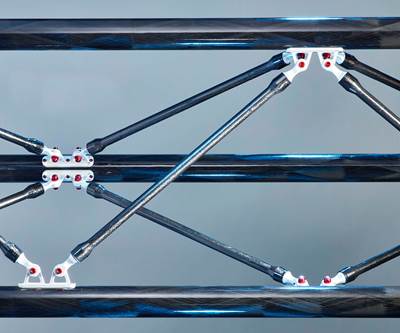

Filament Winding

Solvay showcases low-cost prepreg and parts approach using Cygnet Texkimp filament winder

High-speed, tailored preforms are used with Solvay double diaphragm forming (DDF) and compression molding to produce cost-effective, medium-volume auto and aero parts.

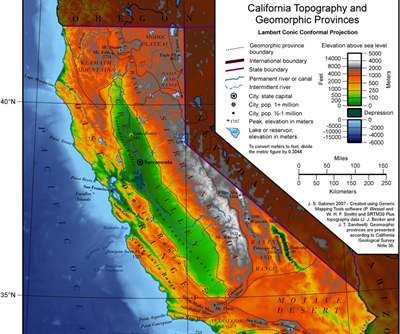

WatchComposites' role in seawater reverse osmosis desalination

Part two of a two-part series on the role of composites for meeting California’s 21st-century water needs.

Read MoreComposites help take the waste out of wastewater

The role of composites for meeting California’s 21st century water needs.

Read MoreIACMI: Driving innovation in the advanced composites industry

Since its start in 2015, the Institute for Advanced Composites Manufacturing Innovation (IACMI) has come a long way in its mission of advancing composites innovation. CTO Uday Vaidya reflects on the past five years.

Read MoreRock West Composites expands filament winding facility

Rock West Composites expands its operation with the acquisition of new winders and ovens, establishes filament winding center of excellence.

Read MoreScottish rocket facility unveils advanced materials production methods

Orbex offered a peek into its Scotland-based rocket facility, unveiling its carbon fiber winding equipment and 3D printed single piece rocket engines, as well as its new Mission Control Centre.

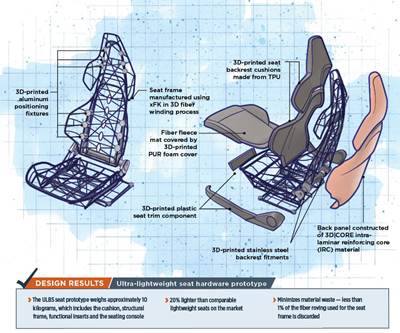

Read More3D filament winding enables vehicle seating concept

Multi-company collaboration uses xFK in 3D and additive manufacturing to develop an ultra-lightweight seat for hypercars and future mobility platforms.

Read MoreAlbany International acquires CirComp GmbH

German innovator in RTM will help Albany Engineered Composites accelerate technology development in thermoplastic composites

WatchCorebon expands induction-based composites production into new facility

Results for cutting CFRP cycle time to be presented at Carbon Fiber 2019 conference.

WatchComposites industry events focus on recycled carbon fiber, filament winding

CETMA and Suez present a workshop on recycled carbon fiber, MF Tech announces global filament winding convention, and SAMPE 2020 abstracts are due Nov. 15.

Read More