Filament Winding

Roth Composites Machinery delivers customized filament winding system

Three-spindle system for the manufacture of hydrogen tanks boasts a flexible impregnation station and enhanced automation with a 40% increase in performance.

Read MoreAxiom Materials announces narrow slit tow prepregs for electric, CNG and hydrogen-powered vehicles

High-temperature carbon fiber tow prepregs are compatible with AFP and filament winding processes for the development of large structural parts such as lithium-ion battery containers or pressure vessels.

Read MoreEngineering Technology publishes downloadable product overview

Filament winding specialist Engineering Technology Corp. has published a downloadable company and product overview that provides a summary of the filament winding software, systems and technologies available from the company.

Read MoreSTELIA Aerospace Composites advances hydrogen storage

STELIA Aerospace subsidiary converts aero experience into industry-leading storage efficiency for fuel cell applications.

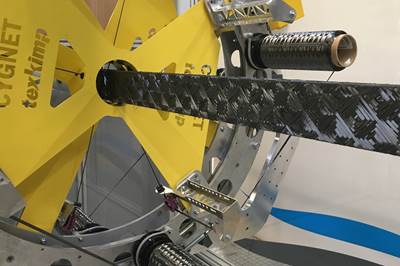

Read MoreNWCC, Cygnet Texkimp collaboration to advance data on winding capability for composite parts

Research project to demonstrate damage tolerance and impact resistance of composite parts manufactured with new multi-axis winder and 3D winding technologies for further development and commercialization.

Read MoreFaurecia showcases composite hydrogen demonstrator for commercial vehicles at Auto Shanghai event

Seven-tank hydrogen storage system designed to provide more than 700 kilometers of autonomy for long-distance and high-load commercial trucks.

Read MoreIncreasing demand for composite driveshafts leads to automated production

California-based fabricator ACPT Inc. worked with machine suppliers to build an innovative semi-automated production line featuring an automated filament winder.

Read MoreHuntsman Advanced Materials resin systems meet composite pressure vessel requirements

Araldite resin systems cover wet and towpreg filament winding and RTM manufacturing processes for increased productivity and greater part consistency.

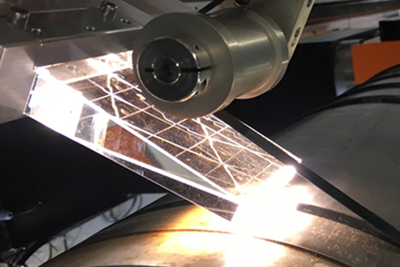

Read MoreHeraeus, University of Sheffield AMRC partner to develop innovative composite technologies

Tier 2 membership enables Heraeus Noblelight to explore filament winding capabilities using its humm3 technology for rapid layup of thermosets, dry fiber and thermoplastics.

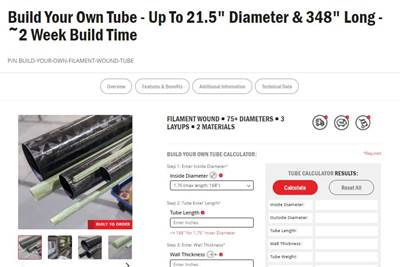

Read MoreRock West Composites offers custom filament-wound tube website feature

Customers can now define their own filament-wound tube specifications per a build-to-order ecommerce transaction. Over 450 base options, 75 mandrels and two materials are available.

Read More

.jpg;maxWidth=300;quality=90)