Filament Winding

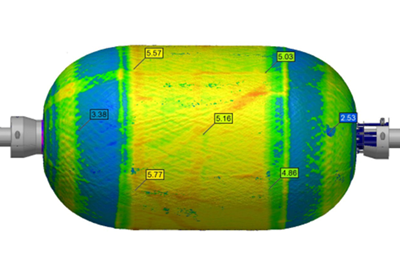

NCC’s all-composite Type V tank demonstrates future composite space tank technology

SpaceTank project delivers a 96-liter carbon fiber composite tank with 4.0-5.50-millimeter nominal wall thickness for 30% weight savings in launch vehicle and satellite propellant tank applications.

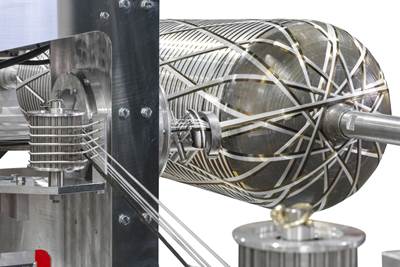

Read MoreFraunhofer IPT develops thermoplastic composites in hydrogen storage, engine blades and more

Active in laser-assisted tape winding and in-situ consolidation of thermoplastic composites since 1988, the IPT in Aachen, Germany continues to push new materials, applications and Composites 4.0 digital processing.

WatchRoth Composite Machinery introduces the FWA 1 Duplex filament winding machine

Dynamic, multi-spindle machine enables the winding process to occur on both sides of the spindle, reportedly halving production time.

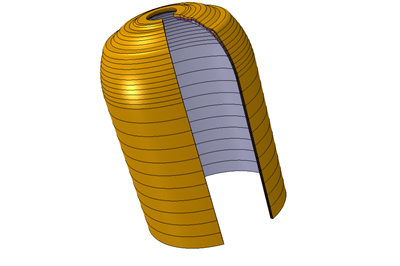

Read MoreWoundSIM software tool simplifies design and simulation of composite pressure vessels

Rapid and efficient tank design process is achieved via an integrated FEA software translator, advanced parametric optimization, simulation and load case testing and post-processing capabilities.

Read MoreCreating stronger composites through nature-inspired, Helicoid designs

Helicoid Industries claims 50% increased toughness, impact strength and reduced material, weight and cost versus quasi-isotropic “fail-safe” designs.

Read MoreSolico, Rondal collaborate on an all-composite halyard winch

The winch is comprised of a carbon fiber prepreg winch housing and filament-wound carbon fiber winch drum which contributes to stability improvements and overall efficiency in marine applications.

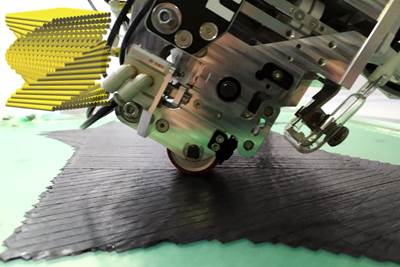

Read MoreComposites Evolution showcases high-performance prepregs, novel thermoplastic UD tapes

Composites Evolution highlights its Evopreg prepreg family, as well as PA6 tapes reinforced with UD carbon fiber for ATL, filament winding and compression molding.

Read MoreMikrosam celebrates commissioning of world's largest production line for CNG and hydrogen tanks

Turnkey project integrates four filament winding machines, two large ovens and multiple robotic lines and buffering stations to produce 60,000 tanks per year.

WatchCorrosion-resistant resins enable FRP petrochemical plant equipment

Spanish fabricator Ollearis used AOC resins and glass fiber filament winding to meet design and cost requirements for combustion unit tank and pipes.

Read MoreMold release for winding and wrapping

In this Digital Demo, Scott Waterman, Global Sales Director at AXEL Plastics (Monroe, Conn., U.S.), outlines the unique differences of filament winding and wrapping that affect the selection and usage of mold release. (Sponsored)

Watch

.jpg;maxWidth=300;quality=90)