Filament Winding

Composite-metal joining, braided preforms enable next-generation aircraft design

Collins Aerospace invests in new joining, preforming and infusion techniques to target aircraft design needs for reduced weight and lower-cost manufacture.

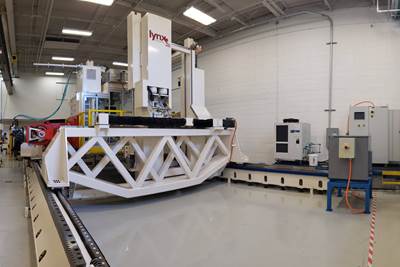

WatchIndustrial-scale wave energy system enabled by mobile filament winding

Sweden-based CorPower Ocean designed its 9-meter-long, filament-wound GFRP buoy prototype for high-efficiency, durable wave energy generation and fast, on-site manufacture.

WatchCAMX 2021 exhibit preview: MF Tech

France-based MF Tech meets aerospace, automotive, sports and industrial application needs with its robotic filament winding solutions.

Read MoreCAMX 2021 exhibit preview: McClean Anderson

McClean Anderson continues to innovate with the release of Ocelot, a filament winder machine control software that enhances input/output possibilities, external hardware integration and improves backup capabilities.

Read MoreLivMatS biomimetic flax fiber Pavilion opens to the public

Made entirely of filament-wound flax fiber, the livMatS Pavilion combines integrative design, robotic fabrication and sustainable materials for a highly innovative, bio-inspired construction.

Read MoreCAMX 2021 exhibit preview: Autonational

Autonational highlights its capabilities in automated filament winding and CNC machining, including a recent case study from a utility vehicle manufacturer.

Read MoreCAMX 2021 exhibit preview: Cygnet Texkimp

Cygnet Texkimp hopes to accelerate the use of composites in hydrogen technology with its new Filament Winding Innovation Hub, which will enable customers to explore every aspect of the filament winding process.

Read MoreEngineering Technology FWC10 control system boosts filament winder productivity

Compatible with Windows 10 OS, the advanced system brings aging filament winding machines on par with new-generation functionality.

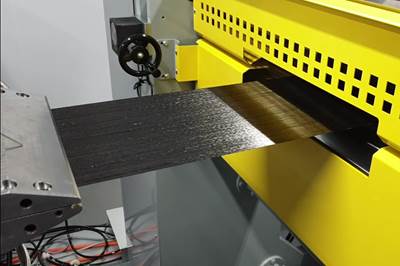

Read MoreCevotec fiber patch placement improves storage efficiency of composite tanks

Cevotec’s solution is to apply carbon fiber patches to the dome areas of Type IV pressure vessels, which reportedly yields 15% in material, weight and cost savings.

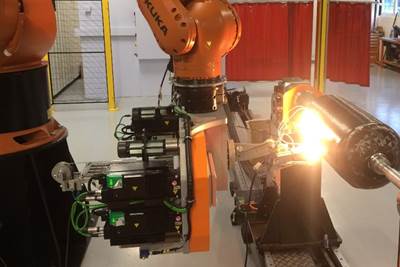

WatchMcNAIR Aerospace Center installs Heraeus Noblelight humm3 technology

Composites heating technology will comprise of a fully integrated system with a plug-and-play head module to further extend AFP and cylinder production capabilities.

Read More

.jpg;maxWidth=300;quality=90)