Filament Winding

Manufacturing tech for scalable Type V hydrogen tank fabrication, CFRP lifecycle management

Cygnet Texkimp’s Multi Roll Stack and composite recycling technology catalyze ASCEND program’s mission to optimize aerospace, automotive hydrogen storage and CFRP sustainability.

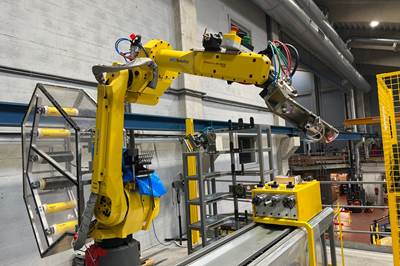

Read MoreCompoTech promotes automated filament winding machine options

Custom-built, turnkey automated winding and filament placement equipment create new possibilities for manufacturers to cost-effectively produce high-strength structural carbon fiber components.

Read MoreMikrosam filament production line supports Amargo tank production

Mikrosam system features will support the production of Amargo’s chemically resistant pressure vessels or hydrogen storage in industrial plants.

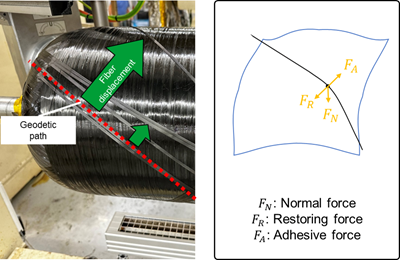

Read MoreIVW research to better determines fiber friction coefficient

Highly variable system development contributes to the increasing precision and efficiency in the manufacture of filament-wound composite components.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreAddcomposites highlights novel composites manufacturing developments

AFP-XS and AddPath updates, new AFP and continuous AM systems, upcoming webinars and blog content are available to interested industry members.

Read MoreVIDEO: Sustainable pressure vessel systems for heavy-duty vehicles

Automotive and filament winding experts at Voith Composites showcased their Type IV hydrogen storage tanks at JEC 2023. These 350-liter pressure vessels, manufactured with recycled carbon fiber, are primarily designed for heavy-duty vehicles.

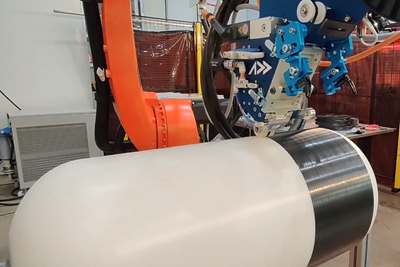

WatchAFPT combines tape winding, placement into one tool

Typically separate processes, the company’s new vessel winding head (VWH), merged with a multiple tape laying head (MTLH) progresses composite pressure vessel development.

Read MoreThermally conductive mandrels enhance filament winding capabilities

CAMX 2023: Acrolab features its Isomandrel technology, which redistributes high thermal energy uniformly over the entire filament winding mandrel surface, providing predictable and consistent energy input into the part and removing the need for oven cure.

Read MoreBroadband flash lamp heat source improves material deposition

CAMX 2023: Humm3 technology is a broadband flash lamp heat source for AFP, ATL, filament winding and more composite applications, delivering power previously only available from lasers.

Read More