Injection/Overmolding

License to speed for composites manufacturing

RocTool pushes composites into new markets with its high-speed induction heating technology for molding.

Read MoreComposites for heavy truck: Tough-duty inspection cover

Thermoplastic composite reduces weight, cost, corrosion, extends maintenance intervals.

Read MoreHighlights: JEC Europe 2014

Composites enable high performance and lower weight in washtubs, wheelchairs and engine exhaust cones. Plus new, ultralight materials.

Read MoreAonix Advanced Materials system combines material, machinery

Ottawa-based company develops turnkey technology for high-performance, thermoplastic composites at volumes of up to 1 million parts per month.

Read MoreExceeding the Limits

Three novel fiber-reinforced, high-temperature thermoplastics promise part designers a broader means to push past performance barriers.

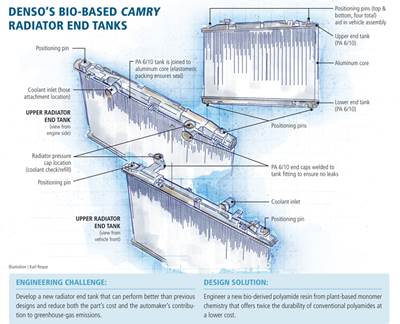

Read MoreCleaner and greener: Bio-based end tanks

Plant-based polyamides break high-cost/low-performance paradigm to meet the demands of a challenging Toyota underhood application.

Read MoreSpare wheel well: Functional integration

Gas-assist injection molding enables one-piece, one-shot thermoplastic composite/metal hybrid.

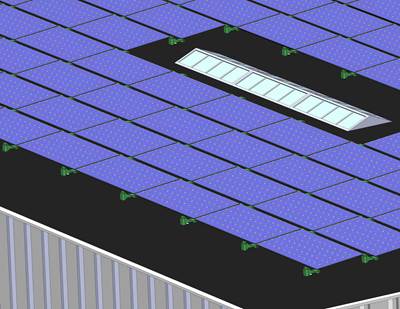

Read MoreSolar panel supports: New rooftop system uses lightweighting strategies

A solar-energy start-up's prototype solar photovoltaic (PV) modules harnesses the benefits of injection-molded composites to solve problems often encountered in flat-roof solar-panel installations.

Read MoreUnder the hood: Thermoplastics tackle tough jobs

Reinforced plastics save weight and cost, increase underhood productivity.

Read MoreMaintaining fiber length in complex 3-D designs

Award-winning composite pallet showcases new LFT molding process from South Africa.

Read More