Spare wheel well: Functional integration

Gas-assist injection molding enables one-piece, one-shot thermoplastic composite/metal hybrid.

In most passenger cars, there is a recessed storage space in the trunk for a spare wheel-mounted tire, a jack and a lug wrench. Traditionally produced in stamped steel, and more recently in aluminum, this spare wheel well (SWW, also known as a spare wheel baffle) is a large, heavy, tub-like component that also plays a role in vehicle structure and crash safety. Because it is exposed to the elements, its underside is prone to corrosion. That means it’s an excellent candidate for composite-for-metal conversion.

Indeed, European and Asian automakers have been doing such conversions on select platforms for almost two decades. Initially this was done on vehicles with low annual production volumes (150,000 or fewer). The lower tooling costs for composite tubs vs. metal tubs had an immediate positive impact on the OEMs’ bottom lines. As confidence in such conversions grew with experience, the composite tubs were extended to vehicles with moderate build volumes (150,000 to 300,000). Today OEMs are considering them for even higher volumes.

A significant step forward in composite SWW development was recently taken with a new material/process combination that debuted on the 2011 model year Audi A8 luxury sedan from Audi AG (Ingolstadt, Germany). It might well be the first use of short-glass pelletized thermoplastics in a SWW and is said to represent new levels of functional integration and weight reduction in this application.

The Audi tub structure is a hybrid — a 60 percent short-glass-reinforced, flow-enhanced polyamide (PA) 6 resin (Durethan BKV 60 supplied by LANXESS AG, Leverkusen, Germany) comolded with a long perforated aluminum strip. The combination is gas-assist injection molded by voestalpine Plastics Solutions (Putte, The Netherlands), which produces the one-piece tub in one shot.

The tough tub weighs only 9 kg/20 lb, yet it carries 70 kg/154 lb of additional components — seven times its own weight — including a full-size spare tire/wheel, a battery, a car jack, an air-suspension compressor and other electronic control units (ECUs). It reduced the part count from the steel benchmark of 15 to 1, and it cut capital investment by 70 percent and cut part cost and weight by 30 percent each, all without sacrificing ease of assembly. Further, the mass reduction is said to be equivalent to a CO2 emissions reduction of 499 kg/1,100 lb annually. But the full impact of this development is best appreciated against the backdrop of composite SWW history.

Beginning with the back story

Switching from metals to composites in this application brings benefits to automakers, tier integrators and even consumers. The low tooling costs are particularly attractive on small-volume or niche-model vehicles. The part weight usually drops 30 to 50 percent, boosting fuel economy. Secondary operations (e.g., priming and painting) can be reduced or eliminated, and system costs tend to be about 20 percent less, on average.

Owing to the increased design flexibility and parts consolidation that is possible with plastics, composite SWW tubs can offer more ergonomic features and greater stowage capacity, yet they take up less packaging space in the trunk area without raising processing costs. Because polymeric materials are well known for their sound-damping properties, composite SWWs reduce noise/vibration/harshness (NVH) values. The quieter ride is a real plus, particularly on luxury platforms. Of course, rust and galvanic corrosion issues that plague metal parts are eliminated, and composites offer better resistance to dings and dents. Composite SWWs also enhance energy management during rear- or side-impact crash events.

The switch also provides some benefits during vehicle build. Because most composite SWWs can’t handle E-Coat (electrodeposition coating) temperatures, they aren’t affixed to the body-in-white (BIW) as early as metal units, making it easier for line workers to access wiring and other components in this area of the vehicle prior to trunk closeout. Ironically, installing the SWWs later can reduce assembly line space requirements and costs by eliminating a station normally used to close out E-Coat drip holes in metal SWW pans. Also, in many plants, the same robot that installs the windshield can install the composite SWW because both applications can make use of the same adhesive.

Over the years, a number of different composite material and process options have been tried, beginning with compression-molded sheet molding compound (SMC). To further reduce weight and cost and to increase production speed for a greater volume of vehicle builds, SWW technology moved to compression-molded glass mat thermoplastic (GMT), then to compression-molded direct long-fiber thermoplastic (D-LFT) followed by injection-molded pelletized LFT — all with polypropylene matrices.

Each of the resulting composites offered its own set of benefits and challenges in the application.

On the plus side, SMC was durable, rustproof and relatively easy to paint. It also exhibited high stiffness and strength and the thermal and chemical stability to survive E-Coat, so it could be mounted directly to the BIW early in the build sequence. Like all composites, SMC provided the opportunity for parts consolidation and increased functionality via molded-in design features, while reducing the total tooling costs for a given platform vs. metals. On the minus side, however, it was less tolerant to damage than reinforced thermoplastics, and it was prone to brittle failure in a crash. And although SMC was lighter than aluminum or steel, it was the heaviest of the composites that have been used.

GMT was lighter, and it processed faster than SMC because there was no need to wait for crosslinking. To keep the weight and section thickness down, tub designers could integrate unidirectional glass and fabric-reinforced charges selectively in areas that require higher mechanicals. GMT was more damage-resistant than SMC or metals and had superior crash performance (with ductile failure modes). However, because it was sold as a semifinished sheet product, GMT proved to be a relatively expensive option.

D-LFT and pelletized LFT also vied for market share. They helped reduce part costs, but often at the expense of added weight, due to the increased section thickness and/or the need for steel or aluminum reinforcement to bolster stiffness. All the polypropylene-based thermoplastic offsets lacked the thermal stability necessary to survive E-Coat, so it was necessary to install them later in the vehicle build sequence. They also were very difficult to paint. Fortunately, integral pigmentation (generally in basic black) eliminated the need for that operation.

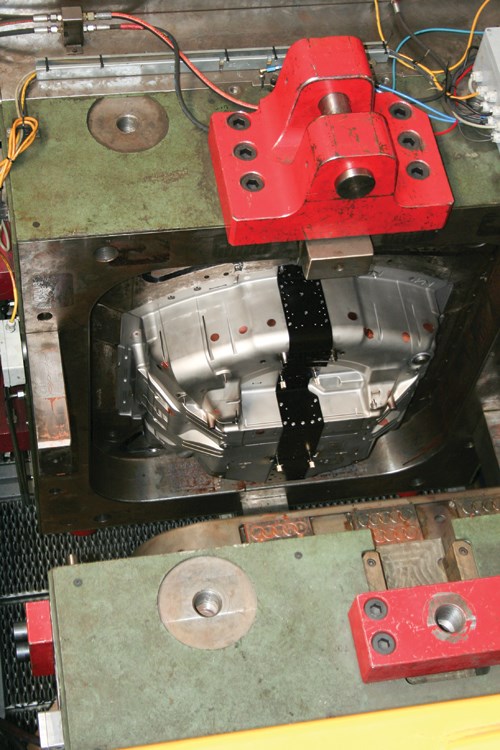

The Audi A8 SWW module, the result of three years of close development work between Audi engineering and voestalpine, sports a number of unique design aspects that mitigate the negatives of other material and process combinations and earned it SPE Central Europe’s 13th Automotive Innovation award in the Body Exterior category in late 2010. Chief among the design features are two large gas channels in an X shape that bisects the part (running from the driver side to the passenger side of the vehicle). These channels are produced during the initial phase of molding when inert gas (nitrogen) is pumped into the tool to form the tubes. Not only does the gas-assist process remove (hollow out) material from the neutral axis (where it’s doing no work) in an otherwise solid-walled injection part, but it also simultaneously increases stiffness and reduces weight. As an extra measure of safety, a strip of perforated aluminum is insert molded during the injection cycle. It bisects the tub width (see photo #2). In the event of a severe crash, the strip restrains the battery and ensures that it stays in place.

Developing the part

A division of Austria-based steel conglomerate voestalpine AG, voestalpine Plastics Solutions specializes in the design and manufacture of structural and semistructural injection- and compression-molded plastic products. The company also has expertise in plastic/metal hybrids (PMHs), like the Audi A8 SWW module. It supplies leading automotive and truck customers throughout Europe, as well as solar, mobility and industrial-packaging markets. Early goals for the development team included parts consolidation, increased functional integration and cost and weight reduction. However, Audi engineering also wanted the composite tub to provide greater torsional, tensile and flexural stiffness to counterbalance loss of stiffness in the rear of the BIW that can result when an aluminum tub is replaced by a composite tub.

“Given the requirement that we had to make the module stiffer, as well as lighter and lower in cost,” recalls Frank Voge, voestalpine’s business development manager, “we spent a lot of time working with materials suppliers, design and simulation firms, and toolmakers to evaluate different materials and process combinations to see which selection met our targets most efficiently.”

The process included some design-of-experiments work and many simulations as designers looked at multiple options involving glass mat and glass rovings, steel inserts and, on the processing side, compression molding, water injection and other methods. Thermosets were considered, but Voge notes that thermoplastics offered more opportunities for functional integration. Notably, polypropylene was eliminated because its elastic modulus is lower than that of polyamide. “In the end,” he says, “the solution that allowed us to get the best combination of stiffness, mass and cost was a glass-reinforced polyamide part produced with gas-assist injection molding.”

“Gas-assist injection allowed us to selectively increase stiffness at critical locations while lowering mass,” reports Jeroen Dictus, voestalpine’s project manager for Audi projects. “Injection molding, of course, is always best for parts consolidation and increased functionality, since it allows numerous features that are impossible to form in metal stampings or difficult to do in compression molding to be designed in from the start.” Injection molding also enabled the company to mold in a variety of inserts, including all supports, brackets and mounting hardware. This simplified fixturing and postmold assembly. “And by selecting higher loading levels of a short-glass thermoplastic rather than lower loadings of long or continuous glass,” he notes, “we could mold a much more complex part that filled the tool properly without any feed throat restrictions.”

The PA 6 yields a tough part with high fatigue strength and a thinner nominal wall than polypropylene would have permitted, says Dictus, adding that it also offers good abrasion resistance and reduced NVH values. And the polymer provides a very good surface finish that can be painted easily. “It also has a continuous-use temperature range that is 80°C higher than polypropylene.”

Because the part was designed from the start for gas-assist rather than conventional solid injection molding, there was no need for intermediate prototype tooling, which kept the program costs down and helped move the development timeline along. The team started with a soft (aluminum) gas-assist tool to validate the concept and went immediately to a hard (P20 steel) tool for series production.

“Designing the tool from the start for gas-assist injection was more logical,” says Michiel Nieuwenhuize, sales account manager at voestalpine, “because this way, the design uses just two injection ports/valve gates instead of as many as 23, which would otherwise have been required to mold a part of this size and complexity. In effect, the gas channels act like huge hot runners or flow assists, preventing premature freeze-off during the fill portion of the injection molding cycle.”

Each sizeable valve gate is outfitted with a needle-sealable hot runner tip. This part is critical to ensure that the inert gas doesn’t back out of the gas channel and move into the barrel of the injection molding unit during the pack and hold portions of the injection cycle. The team also found, by means of numerous filling simulations, that the positioning of gas channels and hot drops was critical to ensure uniform freeze-off and to control thickness in the hollow gas tubes that formed during molding. If the gas channels or hot drops are moved a little bit, the gas channels suddenly have nonuniform thickness profiles, or the part won’t fully fill before the molten polymer solidifies, leading to short shots.

Owing to the geometric complexity and high level of functionality desired in the final part, the tub design features numerous undercuts, through-holes and other sharp design features that require significant tooling action (slides). In fact, the production tool, manufactured by Simoldes Aços SA (Oliveira de Azeméis, Portugal), is equipped with six hydraulic and two mechanical slides that are necessary to accommodate undercuts in the design. Two of the hydraulic slides are unique because a robot automatically loads 2x3 M6 threaded inserts (used to mount the SWW on the car chassis) into position at an angle directly on top of the two slides before each molding cycle. The tub is molded on a 2,700-ton press from KraussMaffei Technologies GmbH (Munich, Germany). Because of the high processing temperatures (thanks to the high-flow grade of LANXESS PA 6 resin), an excellent surface finish is achieved despite the high glass loading.

Hybrid reinforcement

A perforated-aluminum sheet metal stamping, used to secure the battery, is insert-molded into the SWW tub. During molding, the metal insert — 849 mm (33.4 inches) long; between 120 mm and 140 mm (4.7 inches and 5.5 inches) wide; and up to 289 mm (11.4 inches) deep — is mechanically bonded to the composite. The molten polymer flows into the insert’s holes and partially encapsulates the profile, forming what essentially amounts to ribbing that prevents the thin metal stamping from buckling under the load. The resulting structure is a specialty that LANXESS pioneered in the European auto industry in the late 1980s. This PMH mixed-material system takes advantage of the best of each technology, offering excellent resistance to bending, compression and torsional loads (via optimum transfer of force between material systems), high energy absorption, dimensional stability and low part weight. It also further consolidates parts and reduces assembly steps while increasing design efficiency and freedom. Although it wasn’t necessary in the case of the SWW tub, LANXESS developed a method for joining multiple steel stampings via specially designed buttons, which transfer loads from one stamping to the next, eliminating the need for welding.

One challenge the team faced with the stamping was consistently locating it within the part. In early trials, it was difficult to hold the strip in position during mold fill, because injection pressures were high (27,000 kN/m2 or 27 MPa) and the flow front became turbulent as the molten polymer encountered the tool’s complex geometry. To ensure consistent positioning, the team made use of extra in-mold fastening devices to hold the stamping in place. Another issue that the team faced was the size and positioning of the perforations in the aluminum stamping; their geometry proved critical to the creation of sufficiently high adhesion to prevent delamination. Reportedly, it took several iterations to arrive at the final design.

Upon demolding, automated postmold finishing operations apply a long-life paint primer and attach four M8 mounting studs and a noise-absorption pad where Audi will later mount the air-suspension compressor. This reduces secondary finishing at voestalpine’s own facility while maximizing assembly efficiency for Audi. The SWW module arrives at the automaker’s assembly plant with all subassemblies connected and ready to attach to the vehicle. The unit is adhesively bonded and mechanically fastened to the BIW after E-Coat. In fact, during vehicle assembly, both ends of the aluminum strip, which come up the sidewalls of the tub, are screwed into the BIW to create a path to ground and prevent static discharge issues. Further, the thermoplastic matrix permits end-of-life recycling.

Speaking about what this program means to voestalpine, sales director Huibjan Braafhart says, “This module was an important pilot project to show the market our full capabilities. Not only is our customer pleased with the results, but the program has generated strong interest among other automakers. We are working on next-generation innovative and value-added solutions that exploit the benefits of plastics and composites to reduce weight and cost and increase functional integration.”

Related Content

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

Automated solution: New presses for SMC molding process

Using glass/polyester sheet molding compound (SMC) that it formulates and manufactures in-house, Stahlin Non-Metallic Enclosures (Belding, Mich.) produces composite boxes and enclosures for electrical systems and components.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)