Maintaining fiber length in complex 3-D designs

Award-winning composite pallet showcases new LFT molding process from South Africa.

Discontinuous glass fiber-reinforced polypropylene (PP) is a popular composite material in automotive, building and construction, and lawn and garden applications. It offers a good balance of high stiffness-to-weight, broad chemical resistance, good weatherability, all-around toughness and durability and, of course, low cost.

Maintenance of postmold fiber length is critical to achieving good mechanicals, and is what has moved glass/PP from commodity to engineering resin status. Much work in the past two decades has focused on getting longer fibers into the matrix prior to its being placed in a tool, and then preserving that fiber length during the molding process. This led to technology developments that drove an evolutionary shift from precompounded short-glass pellets for conventional injection molding to so-called long-fiber thermoplastic (LFT) pellets (also precompounded) for injection and compression molding and a more recent development, the inline compounding of charges/logs of glass and resin at press side just prior to placement of the charge into an injection or compression press. Ironically, compression-moldable, glass-mat thermoplastic (GMT) composite in sheet form experienced a parallel but opposite trend. Originally offered in continuous-strand, randomly oriented glass mat, which delivered high mechanicals but exhibited less than desirable glass penetration in deep ribs, bosses and intricate design features, the material evolved to shorter chopped-glass mats with optional unidirectional glass and/or engineering fabrics for locations that required additional stiffness. Although molders now have access to all of these diverse material forms and molding processes, no material/process combination is without issues that tend to compromise part design complexity, cost and/or mechanical performance.

Injection molding of short- or long-glass pellets provides the opportunity for rapid cycle times, excellent repeatability and reproducibility (R&R), and the option to create extremely complex three-dimensional (3-D) designs thanks to tooling action. On the downside, feedthroat issues limit the ultimate length of glass that can be injected, and production volumes need to be great enough to justify the high cost of equipment/press time and tooling. Additionally, all the “plumbing” and tooling action that enables production of such complex parts also tends to break glass fibers, reducing mechanical properties in finished parts.

Because there is less flow with D-LFT and very little flow with GMT in compression molding, fewer fibers are broken, so mechanicals are typically higher than those achieved using injection molding. Additionally, tooling and press time are less costly, it’s easier and more economical to mold large parts, and the process is fast and can be semi-automated. Similar to GMT, newer work in D-LFT allows fabrics and unidirectional glass to be added to the charge as it’s placed in the tool. However, compression molding is unable to reproduce the intricate and complex 3-D designs possible with injection molding. For example, in ribs deeper than 55 mm/2.2 inches, glass bridging impedes desired glass penetration. Further, the process cannot produce through-holes. These must be cut or punched after removal. Unless the compression tool is equipped with shear edges, parts also require edge trimming after demolding. Each secondary operation adds cost and time to the production process.

The compression molding/GMT combination best preserves the initial fiber length and, therefore, typically achieves the highest mechanicals in glass/PP parts but also is most likely to limit design complexity. And, as a semifinished good, GMT sheet can be pricier than LFT and D-LFT materials. Unless higher mechanicals and lighter, thinner parts are critical instead of just desirable, the customer may be unwilling to pay the premium.

Design complexity and high mechanicals

Now, a new, modified-LFT injection process called Lomolding seems poised to render unnecessary the trade-off between 3-D design complexity and fiber length/mechanicals that is typically required for large parts in PP/glass and other LFT composites. Ten years in development by the LOMOLD Group (Cape Town, South Africa), the patented process can rapidly produce large, highly complex parts with the intricate design features of injection molding, yet maintains post-mold fiber lengths typically seen only in compression molding. Fiber lengths of 10 to 50 mm (0.4 to 2.0 inches) can be maintained with the new process vs. 3.0 to 4.0 mm (0.1 to 0.2 inch) for conventional LFT injection.

The process also can produce parts with higher mechanicals but with thinner walls and lower mass, which presents cost-reduction opportunities. Because it better preserves initial fiber length, it also improves low-temperature impact strength, a traditional weakness of short-glass PP. Additionally, parts have higher mechanicals at elevated temperatures, greater dimensional stability at any wall thickness, and enhanced creep and fatigue resistance. The upshot is that processors and OEMs get more out of the investment they’ve made in the composite’s reinforcement system.

The Lomolding process also duplicates several unique advantages of injection molding: It is automated, fast-cycling, and has high R&R. And company founder and CEO Pieter du Toit is quick to point out that it is a closed-mold system, so resin is never exposed to air as it is when D-LFT charges are moved from the ILC unit, or when GMT sheet is moved from the oven into the compression molding tool. This eliminates a potential issue with hydroscopic materials, such as nylon and thermoplastic polyester.

Further, the Lomolding process has no trouble producing deep ribs, through-holes, and surfaces with complex geometry, and it eliminates the secondary finishing associated with compression molding. Like compression molding, however, Lomolding leverages the benefits of lower molding pressures, which permit molding against soft skins without tearing or damaging grain, and against polymer fabrics or natural fiber mats without melting or burning. A vented tool avoids air-entrapment that can lead to part porosity and dieseling (burning of plastic as heated gases become trapped between solidifying plastic and the tool).

Lomolding differs from conventional injection in two respects: LOMOLD has customized the control systems and modified the melt-delivery system. Much like bulk molding, a large piston (rather than a screw) is used as a plunger to force the melt into the tool through a single gate (up to 100 mm/3.94 inches diameter; gate size is determined by press size rather than size of shot). The fill segment of the molding cycle is short: a 16-kg/35-lb part can be injected in 7 seconds. That’s a rate 60 percent faster than straight injection molding. Moreover, to injection mold a comparably sized part would require a tool with hot runners and at least eight gates.

Significantly, the melt is delivered at 500 to 700 bar (7,250 to 10,150 psi). This generates far less shear and, at 1/20th the melt velocity of conventional injection, uses roughly half of the latter’s clamp tonnage (1,800 tons vs. almost 3,600 tons). All of this helps prevent glass breakage and reduce shear heating. The resulting reduction in internal part stress also lowers the risk of post-mold warpage.

The plunger/piston face closes off the mold’s bounding wall at the end of the stroke, sealing the tool. During pack-and-hold, a second piston meters out the next shot, so there is no lag between finished part ejection (during mold open) and setup for the next shot (once the tool closes again). Additionally, hot runners are eliminated, which saves capital tooling costs and material, which otherwise would be lost as sprues. Lack of sprues shortens cycle times and eliminates post-mold sprue trimming. Plus, Du Toit says, the long glass fibers help conduct heat away the center of the part. Use of a single gate reduces the number of weld lines and strengthens the weld interface because the fast fill means the material is still hot when flow fronts converge. The one downside of the process, at least from an aesthetics standpoint, is that gate vestige is far larger than with conventional injection. The company, however, has exploited this as a marketing tool by putting a large “L” on the piston’s front face, which leaves an impression in the vestige — LOMOLD Group’s equivalent of “Intel Inside.”

Although the bulk of parts likely to run on the system will be glass-reinforced, Du Toit says the process is equally amenable to carbon fiber, natural fibers or wood flour, because resin temperature can be closely controlled and shear-heating of the melt at the gate is effectively eliminated. This can help processors avoid the cost of thermal-stabilizer packages when molding with reinforcements or resins that are temperature-sensitive.

Proof of concept: One-piece pallet

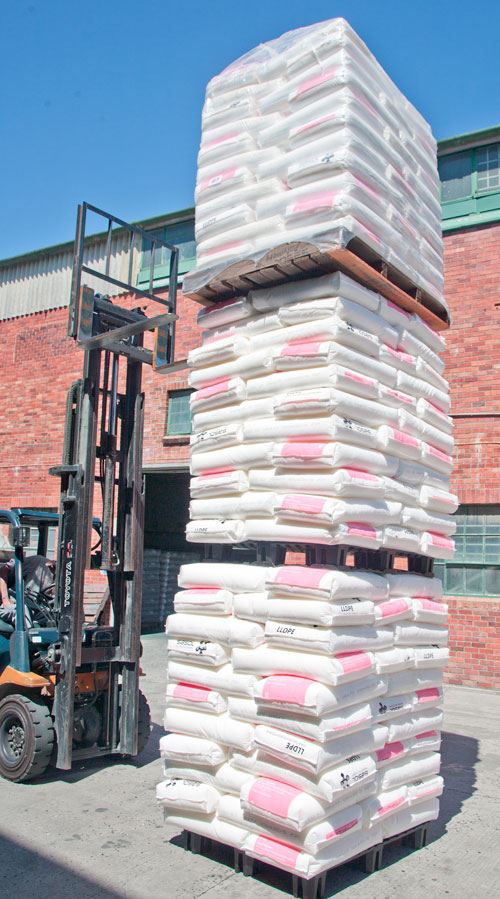

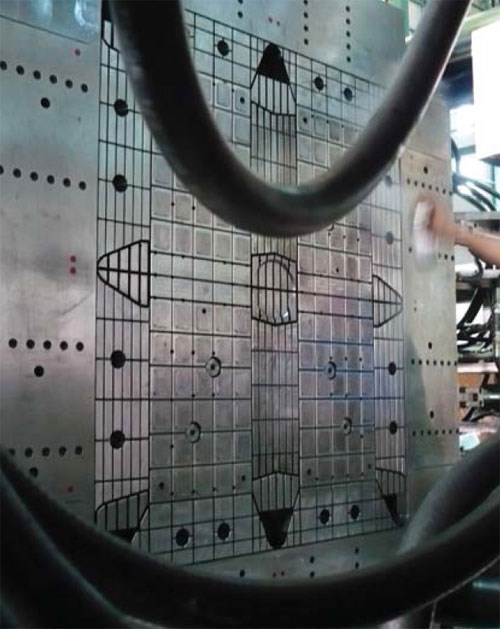

After investing considerable time, money and effort developing the Lomolding process, the company looked for a good application to demonstrate the process’ capabilities. It settled on a composite pallet, the veritable “holy grail” of the materials-handling industry. Designed in-house with input from materials-handling insiders, the one-piece, 21 percent glass-reinforced LFT PP pallet has a complex design and ribbing pattern and is intended to solve a host of problems that long have plagued plastic/metal and composite pallets, totes and dunnage.

There are many reasons why composite pallets should long ago have replaced wood: The generally have far more repeatable dimensions than hand-built wood pallets, and because it is easy to attach tracking devices to the plastic, they are more easily adapted to automated warehousing systems. Composite pallets weigh less than wood pallets, reducing shipping costs for outbound and inbound legs without exceeding legal loading limits.

Wood pallets also can harbor insects and bacteria and, therefore, require costly fumigation and/or heat treatment before crossing international borders. Composite pallets are immune to pests, eliminating border treatments. And composite pallets are more sustainable. Typically, one large tree produces only 6.4 pallets, many of which are used once and then burned or landfilled. Composite pallets offer longer service life —10 years on average vs. three to four years for wood. Finally, they are potentially tougher and, therefore, less prone to breakage or other damage. Thus, they require less maintenance (reusable wood pallets spend up to 25 percent of their service life out of circulation awaiting inspection and repairs). In the case of pallet rental pools, there is greater use of pallets at a given point in time, since far fewer pallets are awaiting repairs.

Despite these benefits and numerous attempts to introduce new designs during the past few decades, composite pallets have failed to penetrate deeply into the materials handling and logistics industries owing to higher cost and, in some cases, lower mechanicals.

LOMOLD believes it has addressed the cost and performance challenges through its unique design and Lomolding materials/process technologies. The company’s one-piece, 122-cm by 102-cm (48-inch by 40-inch) pallet weighs only 16 kg/35 lb and can be produced at injection molding rates, yet offers impact strength of 2.03 J/cm and tensile strength of 88 MPa/13,000 psi. Further, it can bear racking loads greater than 2,750 kg/6,000 lb with deflection of less than 10 mm/0.4 inch, and it can hold a static load greater than 10 metric tonnes/22,000 lb. It delivers mechanical performance and service life far superior to comparably sized/rated wood pallets that weighs 60 percent more (40 kg/88 lb).

Pallet processing steps

For the pallet, the Lomolding process begins like conventional injection molding. Pelletized long-glass/PP is melted and transported via a low-shear extruder into the metering section of the unit. Here, a metering piston pulls back to prepare a measured volume of melt, which is then sent on to a second packing piston, which rapidly, but with low shear, forces the melt into the tool through the unit’s single large gate. Upon mold close, as noted earlier, it seals off the bounding wall of the tool.

The tool used to form LOMOLD’s one-piece pallets weighs almost 25 metric tonnes/55,116 lb and — with 4,382 components, including slides, gate, shutoff, and hardware — is said to be one of the most complex pallet molds in the world. Total cycle time is only 70 seconds. Demolded and cooled parts can be packed for shipping, with no secondary operations required.

Rapid cycling enables production of commercial pallets priced competitively with wood pallets on a lifecycle-cost basis but with far more functionality. Slots for radio-frequency identification (RFID) chip can be molded into the part, allowing easy tracking of the pallet and its contents throughout its use-life. The pallet is fully recyclable at end of life, which is estimated to be a decade or longer.

Taken together, these accomplishments earned LOMOLD Group’s pallet top honors in the Transportation category, during the 2010 JEC Innovation Awards competition this past April. Not content to rest on its laurels, the LOMOLD team has developed a second, multipiece pallet that is lighter, has higher glass loading (for higher performance), and provides greater functionality and cost-savings. These features make it suitable for export use and for single-ownership or pallet pools, particularly when shipping fast-moving consumer goods (FMCGs) — commodities that are shipped and consumed quickly, such as food).

The company’s first pallet production plant, in Huzhou, China, is projected to go online first quarter 2011 and will produce single- and multipiece pallets. Additional plants for pallets and/or LFT pellets are planned in Malta, South Africa, and the U.S. Other projects in the offing include pressure vessels and auto components.

The company has found that its Lomolder injection unit works equally well whether receiving and injecting material from a conventional single-screw extruder that is fed precompounded pellets from a hopper, or from a twin-screw extruder coupled to an inline compounding (D-LFT) unit. The company, therefore, sells its Lomolder injection molding systems fitted for either LFT or D-LFT, together with pultruded LFT pellets (olefin and engineering plastics) for the system, greatly expanding the number of processors who can take advantage of the technology. Machines for both types are produced by Chuan Lih Fa Machinery Works Co. Ltd. (Tainan, Taiwan). Licensing opportunities are available. Additionally, the company is South Africa’s largest rigid-plastics recycler (providing a source of reprocessed resin for less-critical Lomolding applications) as well as Africa’s largest producer of rotomolding powders.

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreRead Next

2010 SAMPE Europe/JEC Paris Showcase

Record crowds and reignited technological development testified to the composite industry’s renewed health and the recent recession’s demise.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)