Machining/Drilling

CFRP: Opportunities in orthopedics

Carbon fiber has a niche, but can it secure a larger piece of a high-growth pie?

Read MoreAircraft composites repair: Plasma’s potential for better bonds

Plasma treatment might be a key enabling technology in the pursuit of certification-worthy, fastener-free adhesively bonded repair patches applied to aircraft primary structure.

Read MoreJEC World 2016 exhibition and product previews

JEC World 2016 will be held in Paris March 8-10. These are some of the products that will be found at the show.

Read MoreAircraft composites repair moves toward maturity

New technologies seek to address the challenges MROs will increasingly face in the age of commercial airliners with composite airframes.

Read MoreTerma Aerostructures: Grenaa, Denmark

This Danish manufacturer of precision composite aircraft parts and components has emerged as a significant player in fabrication of Lockheed Martin’s F-35 Lightning II.

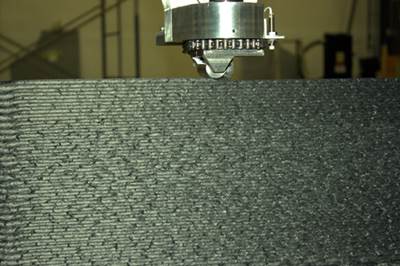

Read MoreThermwood developing large-scale additive manufacturing system

The large-format additive manufacturing machine will produce near net shape parts up to 10 by 10 by 5 ft and provide post-process machining and trimming functions as well.

Read MoreLarge-format CNC routing for large CFRP parts

5-axis CNC routers can provide fast, precision machining of increasingly larger parts, but also rapid payback.

WatchLooking for Lindberghs

Every paradigm-shifting invention throughout human history has been met with skepticism. CW editor-in-chief Jeff Sloan says the composites industry has need of those willing to attempt what most believe impossible.

Read MoreIncremental thinking just won’t cut it!

Composites industry consultant and regular CW columnist Dale Brosius says if this industry is to have a future that goes anywhere profitable, then we've got to get off the road we're on and map out a whole new way to think about the tasks at hand.

Read MoreExelis Aerostructures: Salt Lake City

Braided composite shafts and struts for aircraft are its specialty, but there’s much more to this Utah, US-based rising star.

Read More

.jpg;maxWidth=300;quality=90)