Machining/Drilling

3D-printed hybrid golf club head scores

Multi-material blend joins composite, titanium and brass.

WatchJEC World 2017 exhibit preview

JEC World will be held March 14-16 in Paris. CW previews some of the products and technologies that will be at the show.

Read MoreSize-unlimited OOA composite process enables next-gen system

United Launch Alliance selects Ruag Space for lower cost/improved quality out-of-autoclave manufacture of Vulcan’s composite primary structures.

Read MoreComposite repair: Lessons learned, challenges and opportunities, Part II

In Part II, guest columnist Lou Dorworth says the wind and auto industries can learn much from the aerospace industry in this composites repair commentary.

Read MoreCAMX 2016 Show Report

The 3rd annual joint ACMA/SAMPE-sponsored trade event comes to Anaheim with an exhibition and conference program attractive to professionals across the composites world.

Read MoreWhat I taught at IMTS

IMTS is a big manufacturing show dominated by machines and tools for cutting metals. I was asked to educate the masses about how the machining of composites is different. It was captured on video.

Read MoreComposite repair: Lessons learned, challenges and opportunities, Part I

As aerospace companies look to increase the scope and quality of repairs, through standardized training and increased automation, their lessons learned (outlined here in Part 1 of a two-part examination) can smooth the repair path for other industries.

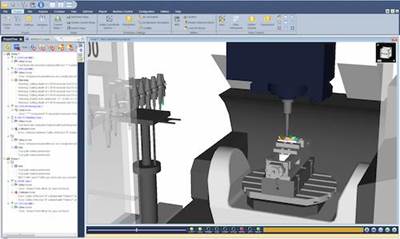

Read MoreCGTech to feature VERICUT Version 8 at IMTS

VERICUT V8 features a new ribbon bar allowing the user to quickly select the required function.

Read MoreClear Carbon & Components: Bristol, RI, US

Breaking barriers in process and complexity, this agile manufacturer is gaining renown as a composites problem solver and champion of Class A cosmetic surfaces.

Read More

.jpg;maxWidth=300;quality=90)