Markets

Ready or not, here come flying taxis and hydrogen

Composites are ripe for entry into a variety of markets, but advanced air mobility and hydrogen storage are poised to put unprecedented pressure on the supply chain.

Read MoreHexagon Purus, Ballard to power Class 6 fuel cell electric truck

Hydrogen truck will take advantage of Ballard’s FCmove fuel cell module and Hexagon’s Type IV hydrogen storage systems and ProPack battery storage for zero-emissions commercial transportation.

Read MoreIljin Hysolus, Korea's leading composite tank producer for hydrogen storage, sets IPO for Sept. 3

Demand for hydrogen tanks is projected to support sustained growth, according to the company.

Read MoreHyPoint, Piasecki Aircraft collaborate to develop, certify eVTOL next-generation hydrogen fuel cells

Initial $6.5 million agreement to culminate in the development of five 650-kilowatt hydrogen fuel cell systems for use in Piasecki’s eVTOL PA-890 compound helicopter.

Read MoreEaton Aerospace qualifies new VITA system, increases satellite payload capacity

Aerospace industry-first valve in tank assembly (VITA) propulsion feed system integrates valves inside a composite propellant tank, increasing payload capacity and reducing considerable rework efforts.

Read MoreHexagon Digital Wave requalifies Type IV cylinders for RNG/CNG transportation module OEM

Requalification is performed via modal acoustic emission (MAE) which identifies structural integrity flaws present in composite pressure vessels, enhancing safety and testing standards.

Read MoreHanwha Solutions acquires Cimarron Composites, aims to be global leader in high-pressure tanks by 2030

Hanwha Cimarron LLC will build new $130 million production facility in Alabama to produce large-scale tanks for hydrogen transport, filling stations and support expansion into tanks for UAM, drones, launch vehicle rockets, defense, rail, cargo ships and more.

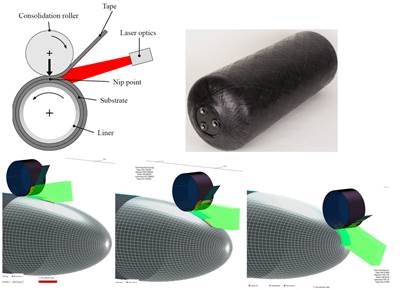

WatchOTOMcomposite develops software for Composites 4.0 production using laser-assisted tape placement and winding

Optical thermal optimization model (OTOM) software enables inline monitoring and control for improved part quality and reduced production time and cost of in-situ consolidated thermoplastic composites and Type IV pressure vessels.

WatchDLR ZLP demonstrates new method for thermoplastic composite hydrogen fuel tank

AFP uses xenon lamp heating and inline QA to achieve innovative design which also uses ultrasonic welding.

WatchUniversal Hydrogen signs deals with three airlines for hydrogen propulsion retrofits

Carbon fiber storage tanks will reduce the Dash-8’s cabin space from 56 seats to 40 seats, but enable emissions-free travel up to approximately 460 miles.

Read More

.jpg;maxWidth=300;quality=90)