Hanwha Solutions acquires Cimarron Composites, aims to be global leader in high-pressure tanks by 2030

Hanwha Cimarron LLC will build new $130 million production facility in Alabama to produce large-scale tanks for hydrogen transport, filling stations and support expansion into tanks for UAM, drones, launch vehicle rockets, defense, rail, cargo ships and more.

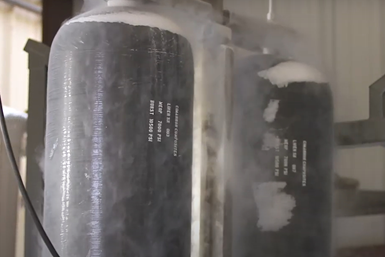

Hanwha Cimarron produces 2,000-liter, Type IV composite Neptune tanks that can store hydrogen at a pressure of 517 bar and transport 1,200 kilograms of H2 in a 12-meter-long tube trailer — four times more H2 than Type I steel tanks used on hydrogen tube trailers in Korea. Photo Credit: Hanwha Cimarron

Hanwha Solutions (Seoul, South Korea) announced in December 2020 that it signed a deal to acquire a 100% stake in Cimarron Composites (Huntsville, Ala., U.S.), a manufacturer of high-pressure, carbon fiber overwrapped tanks. Cimarron Composites was founded in 2008 by Tom DeLay, a 23-year veteran in materials science at NASA. DeLay holds several patents related to lightweight tanks, including patents for high-pressure tanks used in spacecraft.

Hanwha Cimarron currently manufactures large tanks for compressed hydrogen gas as well as tanks for cryogenic fuels used in space launch vehicles. This acquisition is part of Hanwha Solutions’ efforts to accelerate its expansion into the green-hydrogen industry. The company reports that Hanwha Cimarron provides the technology to manufacture tanks for hydrogen tube trailers, ultra-high-pressure tanks for hydrogen filling stations and tanks for aerospace applications, as well as for hydrogen-powered vehicles.

“Including the acquisition costs, we plan to invest at least $100 million in Cimarron Composites by 2025 to establish a strong foundation from which to develop our global hydrogen tank business,” said a spokesman for Hanwha Solutions in Dec 2020. This investment includes funding for the expansion of Cimarron’s production facilities.

Hanwha Cimarron LLC to build $130 million new factory

As reported by Jerry Underwood for madeinalabama.com, Hanwha Cimarron LLC announced plans on August 3, 2021 to invest $130 million in a new manufacturing facility in Opelika, Alabama. Hanwha Cimarron CEO David Jeon said the new facility will help fuel the company’s growth in the carbon overwrap pressure vessel market, catering to the needs of industries including aerospace, drone, defense, marine, rail and gas transport and storage. Hanwha Cimarron LLC will create 261 jobs at its new factory.

“We’re excited about bringing over 200 good-paying jobs to the local area and about being a part of the greater Opelika community,” said Jeon. The Opelika project fulfills part of Hanwha’s plan for the acquisition, specifically its promise to invest at least $100 million in Cimarron Composites production by 2025.

Hanwha Cimarron officials joined Opelika Mayor Gary Fuller at the August 3 meeting of the Opelika City Council to outline the scope of the project. Fuller welcomed Hanwha Cimarron to the East Alabama city’s business community and its new facility in the Northeast Opelika Industrial Park.

Hanwha Cimarron

Hanwha Cimarron Neptune tanks can greatly increase the carrying capacity of hydrogen tube trailers. Photo Credit: Hanwha Cimarron

As described by Hanwha Solutions in its Dec 2020 press release, Hanwha Cimarron produces the 2,000-liter, Type IV composite Neptune tank that can store hydrogen at a pressure of 517 bar. A 12-meter-long hydrogen tube trailer equipped with Neptune tanks can transport up to 1,200 kilograms of hydrogen, which can greatly reduce costs — reportedly transporting four times more hydrogen than Type I steel tanks used on hydrogen tube trailers in Korea.

Hanwha Cimarron claims its tanks are also differentiated by improved safety and efficiency — they can be 100% emptied of their contents, leaving nothing behind. Normally, high-pressure tanks are prone to contracting and damage if contents are emptied below 10% of their capacity. Hanwha Cimarron achieved this advanced performance by applying its design experience and materials gained from developing aerospace tanks.

Hanwha Cimarron has developed high-performance composite tanks used for cryogenic liquid gas storage used by rocket manufacturers and space launch vehicles. Photo Credit: Hanwha Cimarron

Supplying tanks for Elon Musk’s SpaceX Program

According to Hanwha Cimarron, it supplied prototype high-pressure tanks to SpaceX (Hawthorne, Calif., U.S.) and in 2014 began supplying tanks that are used for the Falcon 9 rockets. Hanwha Cimarron has also expanded into producing industrial tanks. Currently, the company manufactures hydrogen tanks, cryogenic liquid gas fuel tanks for space launch vehicles and compressed natural gas (CNG) tanks to a variety of customers, including rocket manufacturers and industrial gas companies.

Cimarron complements and strengthens Hanwha’s hydrogen storage strategy

Hanwha Solutions began pursuing its hydrogen storage strategy by acquiring TK-Fujikin Corp.’s (Busan, South Korea) Type IV tank production business in December 2019. Hanwha Solutions reports that it can now produce tanks for hydrogen-powered drones and passenger cars for the Korean market. Overseas, it intends to use its Cimarron Composites acquisition to produce large-scale tanks for hydrogen tube trailers, tanks for hydrogen filling stations and to expand into tanks for UAM vehicles, aerospace applications and cargo ships carrying liquefied natural gas (LNG).

“Through this acquisition, we will advance our existing tank technology and expand our global tank business,” says Doo-Hyung Ryu, CEO of Hanwha Solutions’ Advanced Materials Division. “Not only will we play a key role in the growing hydrogen economy, we aim to become the global leader for high-pressure tanks by 2030.”

Hanwha Solutions

Hanwha Solutions was formed in 2020 by the merger of Hanwha Chemical, Hanwha Q CELLS and Hanwha Advanced Materials. The company aims to create new synergies and sustainable growth by resolving environmental and climate issues faced by customers and society. It is headquartered in Seoul, South Korea, and has more than 70 locations worldwide.

Hanwha Solutions’ chemical business is said to be the first in Korea to produce polyvinyl chloride (PVC); it also produces polyolefin (PO), toluene diisocyanate (TDI) and chlor-alkali (CA). The company’s Q CELLS business offers a full range of solar energy solutions from residential solar modules and energy systems to large-scale solar power plants. Its advanced materials business produces lightweight composite materials that are helping to usher in the future of mobility.

Related Content

On the radar: Cryogenic testing of composites for future hydrogen storage

Netherlands, U.K., France, Germany and the U.S. build up test capability, look at thermoset and thermoplastic composite materials.

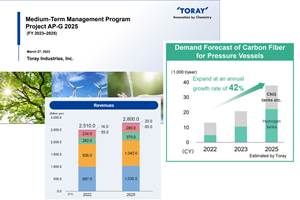

Read MoreToray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreRead Next

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More