Universal Hydrogen signs deals with three airlines for hydrogen propulsion retrofits

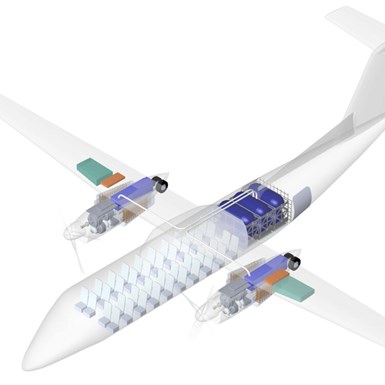

Carbon fiber storage tanks will reduce the Dash-8’s cabin space from 56 seats to 40 seats, but enable emissions-free travel up to approximately 460 miles.

Photo Credit: Universal Hydrogen

Universal Hydrogen (Los Angeles, Calif., U.S.) has signed letters of intent (LOI) with Icelandair Group (Reykjavík, Iceland), Air Nostrum (Valencia, Spain) and Ravn Alaska (Anchorage, Ala., U.S.) to retrofit more than 15 ATR 72 and De Havilland Canada Dash 8 regional turboprops with hydrogen fuel-cell propulsion systems. The LOIs cover replacement of the aircraft’s Pratt & Whitney (East Hartford, Conn., U.S.) turboprops and jet fuel tanks with a pair of two-megawatt (MW) Magnix electric motors and a fuel cell compatible with Universal Hydrogen’s modular hydrogen fuel storage tanks.

Universal Hydrogen’s modular capsules have been designed to overcome the hydrogen infrastructure challenge by enabling a logistics system where they are easily refueled and distributed via the global intermodal-container shipping network and loaded into aircraft at the airport before flight. The twin tanks are contained within a structural frame to form the storage modules and will initially use carbon fiber to contain compressed hydrogen gas with eventual metallic tanks to store liquid hydrogen once development is complete. Universal Hydrogen will also serve as the long-term supplier of green hydrogen to the three airlines.

As reported by Green Car Congress, the planned hydrogen conversions reduce the Dash-8’s cabin space from 56 seats to 40 seats, but enable emissions-free travel up to ~460 miles (740 kilometers). Universal Hydrogen claims that range covers roughly 75% of current routes flown by Dash-8s and that it could expand coverage to 95% of current routes when it is able to offer liquid hydrogen.

Universal Hydrogen’s signed agreements call for retrofit of 11 aircraft for Spain’s Air Nostrum, five aircraft for Ravn Alaska and an unspecified “fleet” for Icelandair Group. No terms for the deals have been announced and LOIs are typically preliminary and non-binding.

As reported by Graham Warwick for Aviation Week, converted aircraft will have operating economics equivalent to or better than the baseline turboprops, according to Universal Hydrogen projections. “At entry into service in 2025, with reductions in the price of green electricity and green hydrogen, increases in the price of Jet A (fuel) and carbon taxes, and with the lower maintenance cost of the fuel-cell powertrain, the per-seat-mile economics of the hydrogen Dash 8-300 will be equivalent to Jet A,” says Rod Williams, chief commercial officer at Universal Hydrogen.

Warwick also reports that a subscale powertrain ground demonstrator has been run at lower power to test Universal Hydrogen’s energy management and control system, and full-scale prototypes of two gaseous-hydrogen capsules and a composite module have been produced. In the coming months, the system will go through a series of technology spirals to take the powertrain to the ultimate two MW level.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.