Materials

CAMX 2021 exhibit preview: Armacell

Armacell highlights its eco-friendly, recycled PET bottle ArmaPET foam solutions for composite parts in a variety of end markets.

Read MoreBucci Composites reveals 22-inch all-carbon fiber wheels for Bentley SUV

The lighter component design — which offers weight savings of six kilograms per wheel — reduces rotational inertia, promises better vehicle handling and meets Bentley’s structural and aesthetics requirements.

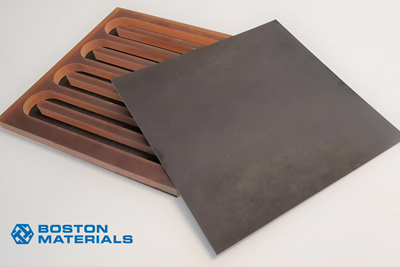

Read MoreCAMX 2021 exhibit preview: Boston Materials

Supercomp, ZRT and Bimetal are three of Boston Material’s z-axis carbon fiber products developed via its patented magnetic alignment process.

Read MoreAtmospheric plasma jet technology rapidly pretreats glass fiber honeycomb sandwich panels

Plasmatreat’s Openair-Plasma system provides composite honeycomb panel manufacturer, MonoPan Composites, with a reliable, high-speed and low-cost dry pretreatment solution for homogeneous wettability.

Read MoreTroubleshooting thermoforming of thermoplastic composites

Challenges with the thermoforming/stamping process and potential solutions addressing the associated parameters and complex material behaviors.

Read MoreKamm Projects launches carbon fiber aero-road bike

U.K.-based composites company combines passion with decades of industry experience to develop a next-gen bike that offers more stiffness, speed, comfort, efficiency, precision and response.

Read MoreCAMX 2021 exhibit preview: A&P Technology

A&P Technology’s new product offerings include slit tape thermoplastic fabrics that can be braided into fabrics up to 60 inches wide.

Read MoreLeveraging large-format AM fuels aerospace flexibility

Ascent Aerospace is known for producing high-quality metallic molds and tools for large aerostructures. Investment in large-format AM has expanded the company’s capabilities.

WatchTeijin launches website to showcase sustainable mobility

Website platform provides easy access to Teijin business groups, automotive sustainability initiatives and will eventually include solutions for polycarbonate resin glazing and carbon fiber.

Read MoreNTU Singapore, Arkema manufacture carbon fiber helmets using Elium resin

Carbon fiber reinforcement increases stiffness, toughness of the helmet’s outer shell and allows it to absorb more impact energy over a longer period.

Watch