Materials

Xenia Materials signs strategic partnership with Shenzhen Jiejiayou

Shenzhen Jiejiayou Material Technology to distribute Xenia’s thermoplastic composites families, XECARB, XEBRID and XEGLASS.

Read MoreArris wins GOOD DESIGN award for optimized composite structures

Company honored for innovative carbon fiber lattice-type truss structure design enabling the future of lightweighting across multiple industries.

Read MoreWhite House Executive Order to build supply chain resilience for carbon fiber

Commitment to comprehensively address U.S. supply chain risks highlights carbon fiber as one of four key products that will be reviewed.

Read MoreBucci Composites completes testing of new carbon fiber wheel

Bucci’s new 22-inch high-performance automotive wheel is all carbon fiber and made via high-pressure resin transfer molding.

Read MoreBye Aerospace eFlyer 2 assembly underway

All-electric aircraft nears FAA certification with composite fuselage and wing assembly, and a current backlog of 717 purchase deposit agreements.

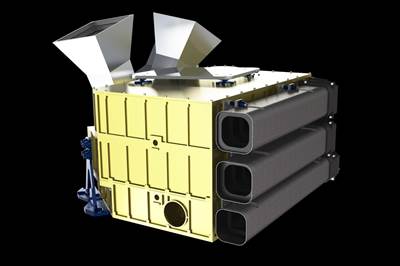

Read MoreÉireComposites to develop Ireland's first carbon fiber satellite optical instrument

Development and manufacture of three composite stray light baffles for the ESA’s ALTIUS satellite will assist in climate change research.

Read MoreInnovative tooling, automation enable new line of composite window wells

Moldmaker and automation specialist Commercial Tool Group provided RockWell with custom compression molds and robotics to enable high-volume, low-cost production.

Read MoreRe:Build Manufacturing acquires Composite Resources

Massachusetts-based investment group Re: Build Manufacturing has acquired South Carolina-based fabricator Composite Resources.

Read MoreThermHex reports a €1 million capital increase

The business growth follows new investments to further optimize and expand ThermHex’s digitalization of its honeycomb core production processes.

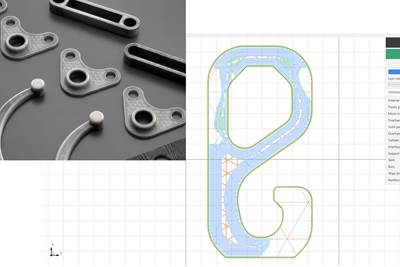

Read MoreAnisoprint launches Aura 2.1 slicing software for continuous fiber 3D printing

New features include “masks” giving users greater control over fiber reinforcement in an easy-to-visualize manner.

Read More