Materials

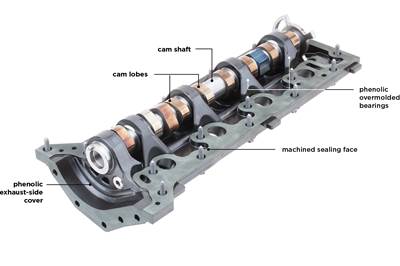

Glass fiber and phenolic prove their mettle in camshaft module

Replacing aluminum, a fiberglass/phenolic module reduces mass and NVH in a prototype structure and speeds assembly line installation.

Read MoreHypetex colored carbon fiber materials made available to U.S. customers

Partnership with distributor Composite Envisions to expand access to Hypetex’s portfolio of naturally-colored carbon fibers.

Read MoreFLOKI 6.5 mini racing yacht integrates bio-based Sicomin GreenPoxy resins

Staying true to the roots of its racing class, FLOKI 6.5 is built entirely from bio-based/recyclable raw materials without compromising on performance or processability.

Read MoreCarbon Mobile carbon fiber smartphone unlocks RF signal permeation capabilities

Housing is made from Lanxess Tepex thermoplastics reinforced with 1K continuous carbon fiber using Carbon Mobile’s patented HyRECM process for a “radio-enabled” composite material.

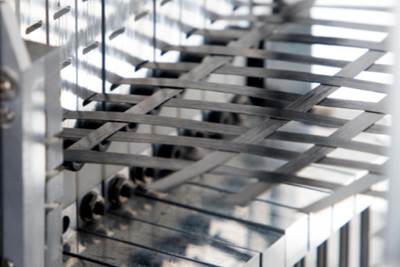

Read MoreAutomated weaving system targets high-performance, high-volume applications

Startup WEAV3D Inc.’s technology produces highly tunable, woven lattice reinforcements for cost-effective, high-volume automotive composites and precast concrete applications.

WatchECOFUNEL program develops thermoplastic compound with increased electrical conductivity

Fiber-reinforced thermoplastic shows eight times more electrical conductivity as compared to the reference material with only a 20% decrease in mechanical properties.

Read MoreImpact tests on RAMSSES ship hull demonstrator show resilience of composites

Damen Shipbuilding and project consortium partners test 6-meter-high, resin-infused composite hull section.

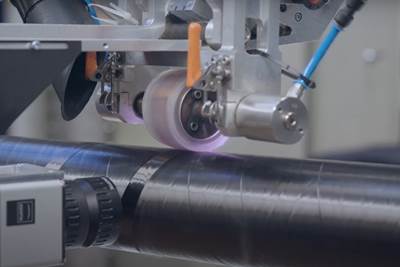

WatchChallenges of laser-assisted tape winding of thermoplastic composites

Practical solutions for process-related challenges in LATW, which has great potential for pressure vessels and storage tanks.

WatchUniversity of South Alabama, MHP engage in research partnership for plastic composite material

ZT-CFRP, enriched with specifically oriented nanoparticles and reinforced with carbon fibers, shows considerable potential when compared to conventional CFRPs.

Read MoreThermwood advances LSAM capabilities with automatic print temperature monitoring

Thermal Sensor Layer Automation system uses a non-contact temperature sensor for continuous temperature data, ensuring precise fusion between large-scale thermoplastic printed layers.

Read More

.jpg;maxWidth=300;quality=90)