Anisoprint launches Aura 2.1 slicing software for continuous fiber 3D printing

New features include “masks” giving users greater control over fiber reinforcement in an easy-to-visualize manner.

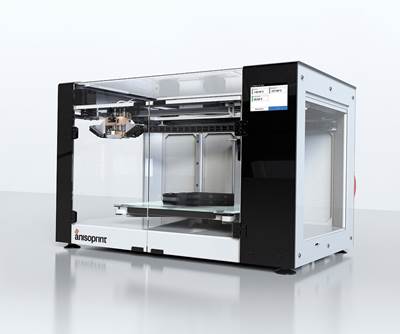

Anisoprint (Esch-sur-Alzette, Luxembourg) a manufacturer of continuous fiber 3D printing systems, has launched an update for its proprietary slicing software.

The new and improved Aura 2.1 Premium is the driving force behind the company’s flagship Composer 3D printer, and enables users to customize and integrate fiber reinforcements into polymer-based composite components.

Packed full of verified printing profiles for a wide variety of polymer filaments, the software is designed to eliminate the otherwise costly and arduous trial-and-error approach to composite 3D printing.

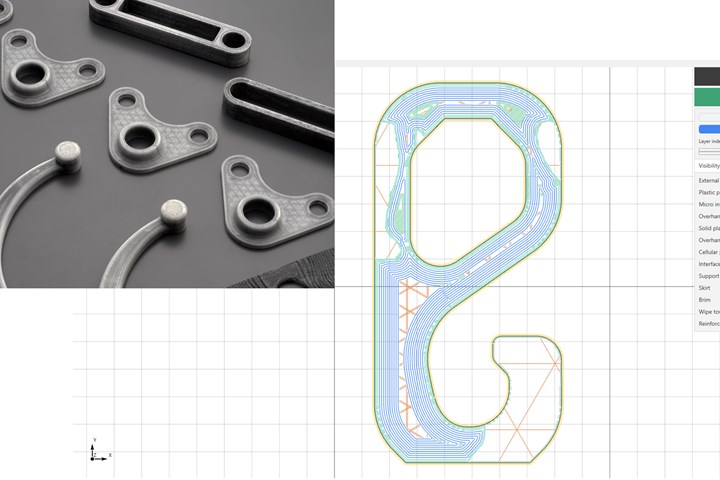

The latest update introduces what Anisoprint calls ‘masks,’ special models that can be added to a part’s 3D file in the slicer’s virtual workspace. The aim is to provide users with greater control over the intricacies of their fiber reinforcements in an easy-to-visualize manner. By intersecting with the original STL file of a component, masks can dictate exactly when and where fiber reinforcements are co-extruded, enabling users to modify the mechanical properties and strength characteristics of printed parts.

As well as highlighting reinforcement locations, masks can also be used to adjust the support positions of a part. After placing a mask, the user can either mark the masked area as a zone of reinforced support or as a support blocker. The former ensures the generation of supports in the specified location, whereas the latter is used to eliminate the generation of supports in the mask, opening up new avenues for designers to save on unnecessary material use while optimizing the structural integrity of their parts.

According to Anisoprint CEO Fedor Antonov, masks are a powerful tool that allow users to create complex fiber layup schemes that match the actual loading conditions of the part. By using masks, customers can select certain areas for enhanced reinforcing or leave them unreinforced to decrease print time and material usage. They also allow selective usage of different infills, fiber/plastic patterns, supports and other slicing settings within one geometrical layer with ease, for a more flexible solution.

The example below shows a part with a hole in the middle. Masks can be used to improve functionality by increasing the stiffness of the component in the horizontal plane. The workflow here has been designed to be highly intuitive and streamlined, as users are only required to place the two masks in the workspace before moving them into the component to form the intersections. At this point, the structures of the masked areas can be fine-tuned, and the Composer 3D printer will do the rest.

The new mask functionality in Aura 2.1 can be used to further optimize printed parts with the end-use application in mind. By adjusting a part’s reinforcement schemes on a layer-by-layer basis, users can customize their builds according to in-service loads.

For a more precise application of the mask, Anisoprint recommends leveraging a third-party topology optimization program. By first determining the exact areas that will be subjected to the most load, users can export the highlighted ‘load zone’ and use it as a custom mask geometry. In this way, human error is eliminated altogether, and the reinforcements are co-extruded in only the relevant sections, as determined by sophisticated finite element analysis algorithms.

According to the manufacturer, the use of topology optimization can lead to weight and cost savings of up to 15% and 25% respectively, all while increasing the strength and deformation stiffness of the 3D printed parts. In the example below, which highlights the load area in blue, deformation has been reduced by 15%, max grid stress by 20%, and max stress in the reinforced sections by 31%.

For users that aren’t looking to 3D print composite parts, Aura is also compatible with other conventional FFF systems, meaning it can be used as a run-of-the-mill desktop slicer. The latest version of Aura can be downloaded at https://anisoprint.com/aura/.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Anisoprint launches ProM IS 500 industrial 3D printer

ProM IS 500 is said to be the first industrial printer for continuous fiber-reinforced high-temperature plastics.

Read MoreAdvancing additive manufacturing to exploit anisotropy

Anisoprint posits continuous fiber composites, not metals, as the material for optimized AM structures.

Read MoreAnisoprint launches basalt fiber for continuous-fiber 3D printing

The material is said to be 15 times stronger than plastic, five times lighter than steel and 1.5 times stronger and lighter than aluminum.

Read More