Molds/Tools

HORYZN emergency UAV harnesses CFRP tooling from Voith Composites

Voith Composites collaborated with HORYZN, a student initiative that leverages CFRP tooling and composites know-how for its Mission Pulse UAV project.

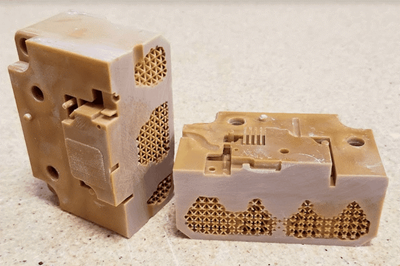

Read MoreFortify, polySpectra awarded $3 million by DOE to advance 3D-printed tooling

Fortify is to develop inexpensive, durable solutions for lightweighting automotive components using polymers, composites and metals, advancing vehicle part commercialization.

Read MoreEx-Core Technologies' Ex-Core 2.0 system features intelligent self-heated tooling, custom-mixed core

Debuted at JEC World 2022, Ex-Core 2.0 is said to slash production costs compared to conventional prepreg sandwich processes and produce lighter, stronger parts.

WatchMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreVoith Composites partnership with Gazechim Group delivers Carbon4Tool tooling system to Europe

With Gazechim Group as the European distributor, Voith hopes to empower faster, easier and more effective CFRP tool manufacturing via its next-generation technology.

Read MoreAirtech 3D-printed composite tooling takes Brumos Racing team to Pikes Peak 100th running

As the Brumos Racing technical partner, Airtech assisted BBi Autosport’s vehicle manufacture by providing aerodynamic enhancements to the Porsche GT2 RS Clubsport via Dahltram printing resins and Print-Tech.

Read MoreJEC World 2022, Part 3: Emphasizing emerging markets, thermoplastics and carbon fiber

CW editor-in-chief Jeff Sloan identifies companies exhibiting at JEC World 2022 that are advancing both materials and technologies for the growing AAM, hydrogen, automotive and sustainability markets.

WatchPRF Composite Materials launches Q.tool prepreg tooling system

Newly developed Q.tool combines RP800 epoxy with 1,020 g/m2 bulk plies for increased layup speed, reduced number of debulks and better surface finish.

Read MoreImprove production with five-axis machines built for composites

Virtually tour (4) USA-Made 5-Axis CNC Machines designed and engineered to help companies improve profits by decreasing cycle times and improving part quality. (Sponsored)

WatchHybrid battery cover: Materials, process decisions

A Q&A with Timo Huber, vice president of HRC’s Advanced Composite Technology Center, discusses material and process considerations for HRC Group’s SMC electric vehicle battery cover research project.

Read More

.jpg;maxWidth=300;quality=90)