Molds/Tools

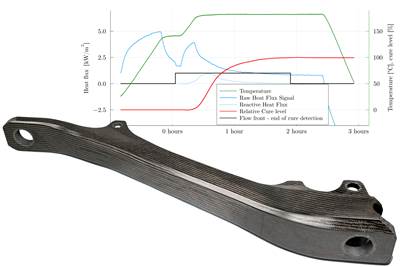

Speeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

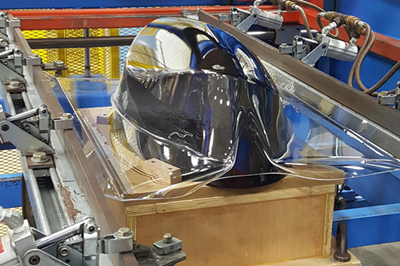

Read MoreCurve Works reaches milestone for modular builds of composite shell structures

Approach reduces cost by 40%, lead-time by 50% and material use by >70% compared to manufacturing in large, one-off mold.

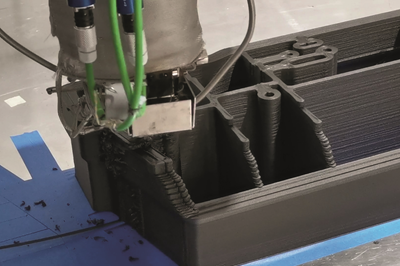

Read MoreCMS debuts hybrid LFAM/milling machine

The machining specialist has developed the first iteration of Kreator, a large-format, thermoplastic composite 3D printer and five-axis milling machine for tooling and jigs.

WatchLarge-scale, robotic-mounted 3D printer aims to expand AM size limits

Italy-based Caracol has developed an extrusion-based, robot-mounted 3D printer to scale up printing capabilities for high-performance aerospace tooling and industrial parts.

Read MoreCEAD and Belotti make large-scale additive composites manufacturing accessible for industry

Strategic partnership combines expertise of additive and subtractive manufacturing into single hybrid solution: BEAD.

Read MoreExOne acquisition accelerates expansion into 3D-printed tooling for composites

Patented 3D-printed sand tooling solution from Freshmade 3D applicable for composite layup, vacuum forming, compression molds, with 30-50% cost savings and design flexibility.

Read MoreMold release solutions for automotive composites

In this Digital Demo, Axel Plastics reviews mold cleaning, sealing and release solutions for leading use in automotive composites manufacturing processes, including SMC, BMC and RTM.

WatchShift2Rail issues call for molding tools to produce composite door, interiors demonstrators

Tenders for molding tools in EU project to manufacture composites using compression molding process or equivalent due by April 22, 2021.

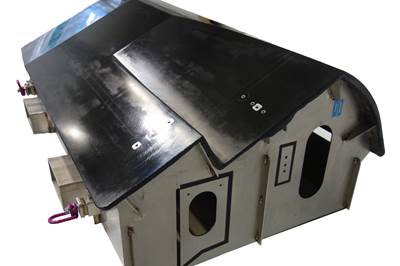

Read MoreDecision SA, Carboman Group unveil new direct mold tooling for aerospace applications

Material selection ensures tool surface and support structure match mold and part CTE for short lead times and highly stable direct molds at temperatures up to 180˚C.

Read MoreInnovative tooling, automation enable new line of composite window wells

Moldmaker and automation specialist Commercial Tool Group provided RockWell with custom compression molds and robotics to enable high-volume, low-cost production.

Read More

.jpg;maxWidth=300;quality=90)