Molds/Tools

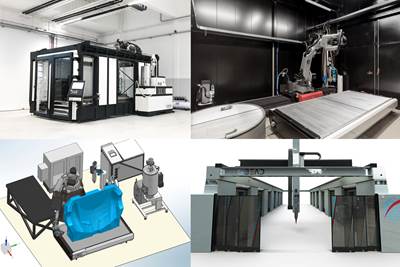

Massivit 3D opens Americas Experience Center

The Atlanta-based facility will showcase Massivit 3D’s large-scale 3D printers, including the Massivit 10000 for composite materials tooling, live demos and will serve the North America and Latin America regions.

Read MoreCAMX 2021 exhibit preview: LUM Industry

LUM Industry specializes in the design and manufacture of highly precise pultrusion dies and molds for glass, carbon fiber or thermoplastic profiles.

Read MoreCAMX 2021 exhibit preview: Symmetrix Composite Tooling

Symmetrix highlights its capabilities to quickly produce precise, complex tooling for a variety of composites applications.

Read MoreCAMX 2021 preview: Ascent Aerospace

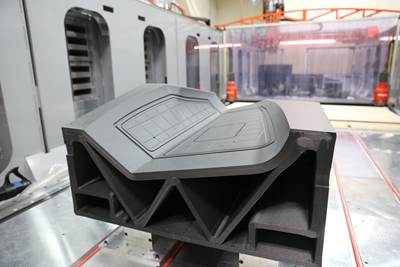

Tooling specialist Ascent Aerospace is emphasizing recently installed capacity to produce tools, molds and fixtures via large-format additive manufacturing at its Santa Ana, Calif., U.S., location.

Read MoreLeveraging large-format AM fuels aerospace flexibility

Ascent Aerospace is known for producing high-quality metallic molds and tools for large aerostructures. Investment in large-format AM has expanded the company’s capabilities.

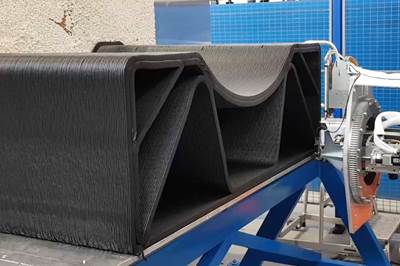

WatchComposites AM research targets wind energy

The U.S. DOE, universities and industry leaders ramp up new efforts and funding to develop 3D-printed composite wind blade molds and end-use blade components.

Read MoreLarge-format, vertical, robotized, fiber-reinforced AM

MTorres joins the large-format AM fray with a system that prints vertically in lengths up to 25 meters.

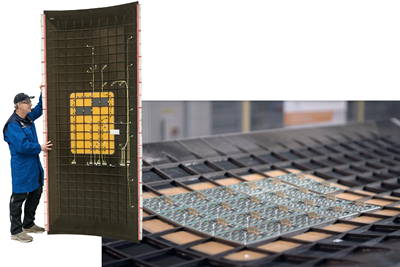

Read MoreIntegrating antennas into composite aerostructures

ACASIAS project integrates Ku-band array antenna in novel AFP orthogrid with drastically reduced tooling for more fuel-efficient, multifunctional CFRP aircraft fuselage panel.

WatchAdapting composites 3D printing to evolving needs

Continuous fiber printing pioneer increases print cell options, size, hybridization and simulation capability for expanded applications.

WatchAirtech 3D-printed resins deliver composite tooling for competitive motorsport vehicles

BBi Autosport joins with Airtech Advanced Materials Group to develop high-performance carbon fiber body panels for its Porsche race cars using Dahltram resins and Print-Tech services.

Read More