Nanomaterials

MIT research proves viability of layering carbon nanotubes in composites

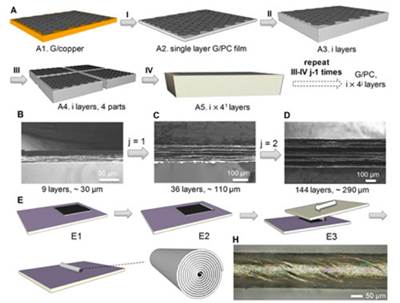

Massachusetts Institute of Technology (MIT) researchers have discovered significant advantages in composites fabrication by stacking layers of graphene or carbon nanotubes.

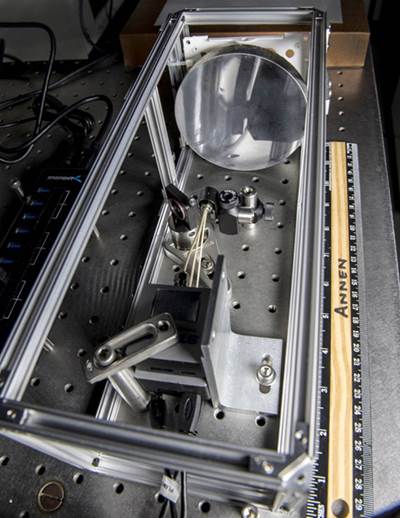

Read MoreNASA considers carbon nanotube mirrors for cubesat telescope

The carbon nanotube/epoxy combination is being evaluated for the fabrication of mirrors on cubesats for planetary space exploration and Earth observations.

Read MoreNanocomp Technologies Inc., Merrimack, NH, US

Its millimeter-length macro CNTs are finally realizing their commercial composites potential, with spacecraft applications leading the way.

Read MoreUniversity of Delaware announces composite medal award winners

The medal is to recognize outstanding achievement in the field of composite materials.

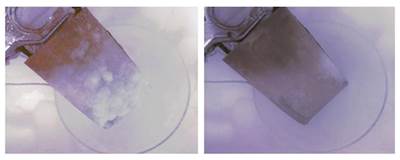

Read MoreGraphene composite could help keep wings ice-free

A thin coating of graphene nanoribbons in epoxy developed at Rice University has proven effective at melting ice on a helicopter blade.

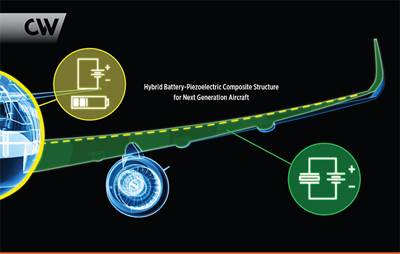

Read MoreMultifunctional composites: past, present and future

Dr. Les Lee at the Air Force Office of Scientific Research and Dr. James Thomas at the U.S. Naval Research Laboratory give insights into the history of multifunctional composites, the drivers for their development and where they are headed.

Read MoreAerocomposites: The move to multifunctionality

Designers envision aircraft components that do more than bear structural loads, but must first confront great complexities to actualize greater functional efficiency.

Read MoreThe end of delamination?

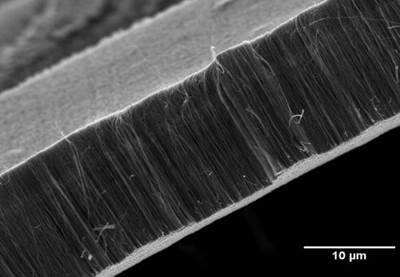

A spin-off from MIT's NECSTlab, N12 Technologies Inc. launches NanoStitch, the world's first vertically aligned CNT product via a continuous industrial process, which bridges adjacent CFRP plies, boosting interlaminar shear and increasing fatigue life by 100%.

Read MoreCNT-enhanced prepregs: commercial & production-capable

N12 Technologies’ NanoStitch and Surface Layer System (SLS) products are part of a new generation of nanomaterials aimed at delivering macro-level benefits in products produced at commercial scale.

Read MoreSPE ACCE 2015 show report

Was this the year, finally, for the big break-through for automotive composites? Maybe, depending on to whom one talked or the presentation one heard.

Read More

.jpg;maxWidth=300;quality=90)