NDI

CAMX offers unprecedented new product access

CAMX 2014, Oct. 13-16 in Orlando, Fla., promises to be North America's largest ever composites trade show and conference. As a result, exhibitors are coming to the event with a wide array of new and existing materials, machinery, software and technology designed to help make composites fabrication faster, easier and more adaptable. CompositesWorld has been gathering information from CAMX exhibitors about what they will be featuring and introducing in their booths. This week's CAMX newsletter offers a preview of some of what you will find on the show floor.

Read MoreSAMPE Seattle 2014 Report

The Society’s reconfigured Spring advanced materials event in Seattle, Wash., attracts speakers, exhibitors and attendees in large numbers and international dimensions.

Read MoreExtending robotic NDT to aerospace certification

Automating current manual testing promises increased speed, reduced cost, earlier damage detection and more detailed analysis of damage growth.

Read MoreSAMPE Europe highlights: Composites face challenges in next commercial airframes

Airbus Research & Technology presented a sobering outlook and emphasized the need for improved cost, manufacturing and robustness.

Read MoreAlbany Engineered Composites: Weaving the Future in 3-D

This 3-D weaver turned composite component supplier pursues a future in 3-D structures through continuous technology development.

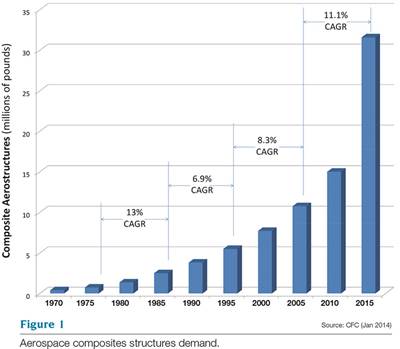

Read MoreThe market for OOA aerocomposites, 2013-2022

In the coming decade, out-of-autoclave technologies will increase composites penetration into primary flight structures.

Read MoreNDI and NDT methods for process control

There are three main nondestructive inspection technologies currently under development to help qualify surface preparation techniques for adhesively bonded aerospace surfaces evaluate the quality of both the prepared surfaces and the final bonded joint.

Read MoreCertification of bonded composite primary structures

OEMs develop technology to quantify uncertainty in pursuit of the no-bolt bondline.

Read MoreGKN Aerospace funds new aero-engine composites technology

GKN-led G5Demo project will pursue new composites technologies at Linköping-based ACAB subsidiary, aimed to cut aero-engine CO2-emissions in half by 2020.

WatchInside a thermoplastic composites hotbed

As production of the A350 XWB ramps up, so does manufacture of the thermoplastic fuselage clips the plane requires. HPC sees how it’s done.

Read More