SAMPE Seattle 2014 Report

The Society’s reconfigured Spring advanced materials event in Seattle, Wash., attracts speakers, exhibitors and attendees in large numbers and international dimensions.

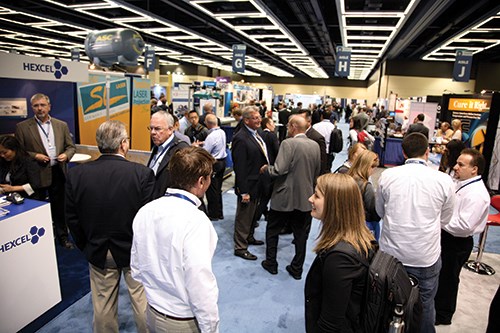

The Covina, Calif.-based Society for the Advancement of Material and Process Engineering’s (SAMPE) Seattle meeting, held June 2-5, attracted nearly 3,500 attendees and drew 233 exhibiting companies, 40 of which were new to the show. Participants hailing from 28 countries gathered in the Washington State Convention Center in the heart of the city.

The vibrant event offered, as always, a slate of excellent presentations, panels and keynotes. Not least was the appearance on Tuesday morning of Jörg Pohlman, the managing director of SGL Carbon SE (ACF, Moses Lake, Wash.). He described that group’s journey from helping to develop an initial car concept for the BMW Group (Munich, Germany) to its current role as a large-scale carbon fiber manufacturer. When Pohlman, an attorney, joined the hush-hush “Project i” in 2008, he recalled, the carmaker faced challenges that included changes in driver demographics and sentiments. “We were tasked with reinventing mobility,” he said. “We wanted a new image and new customers.” By now, most in the composites world know about the results of that secret brainstorming project: the i3 electric and i8 hybrid-electric cars that feature a carbon fiber composite Life Module (passenger cell) atop an aluminum chassis — the Drive Module — that supports a battery-energized electric powertrain (see “BMW Leipzig: The epicenter of i3 production,” uner "Editor's Picks at top right). Pohlman reviewed not only the Life Module, but the i3’s thermoplastic body panels and its seats and interior panels, which incorporate recycled polyethylene terephthalate (PET) reinforced with natural fibers. He also pointed out that the module/chassis concept, popular a century ago with the earliest automakers, enables fast and easy derivative model development. A different body design for a new model year, for example, can be mated with an existing chassis.

Of interest was BMW’s goal of creating a “CO2-neutral” car. “Rather than start with a ‘cool’ design, and then figure out how to manufacture it,” Pohlman pointed out, “we turned it around, and talked first to production people, to figure out how to minimize energy and resource use during manufacturing before committing to a design.” Production of the i3, as a result, consumes 50 percent less energy than any other “green” car, and 70 percent less water, because waterless body painting is involved, he contended. In addition, the energy used is largely renewable, thanks to wind turbines in use at the Leipzig plant and the hydropower afforded by the Moses Lake location. Pohlman revealed that the decision to build its fiber plant in the U.S. was not a popular decision in Germany: “We stimulated some political debate but, in fact, German energy costs five to seven times what we could obtain in Washington.” For those who question the wisdom of shipping carbon fiber precursor from Japan to Washington, and fiber from Washington to Germany for converting, he stated that less than 1 percent of the i3’s value chain energy is represented by shipping logistics. Further, materials are transported by ship rather than rail, again, out of consideration for the car’s carbon footprint. Because carbon fiber supply is the limiting factor in the supply chain, and more than 50,000 i3s will be rolled out, SGL ACF has increased fiber production of its 50K fiber and has begun work on a third building that will ultimately increase annual nameplate capacity to 9,000 tons by the end of 2015 (see “SGL Automotive Carbon Fibers expands Moses Lake facility . . . again,” under "Editor's Picks"). Pohlman says the 50K fiber is “totally sufficient for our purposes.”

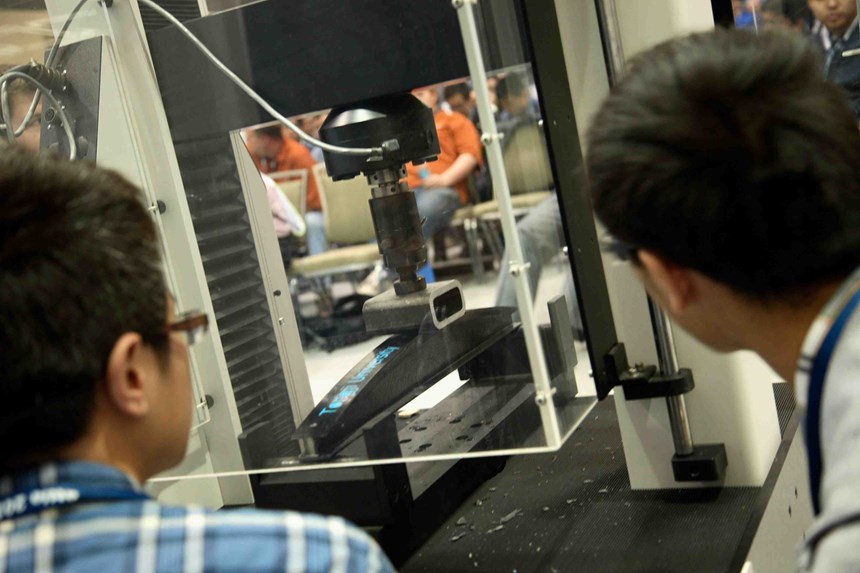

Of high interest was a panel on additive manufacturing (AM), chaired by Brett Lyons of Boeing Research and Technology (BR&T, Seattle, Wash.), which looked at a spectrum of 3D printing approaches. Panelist Ian Ashcroft of the University of Nottingham (U.K.) described his group’s work on topology optimization to develop the most efficient distribution of material in a part. He pointed out that AM is great at capturing and building very complex parts, but a complex part requires a more complex model mesh as well; his work on Quadtree and Octree data structure and nonlinear optimization is aimed at making 3-D printed parts better. In a wild contrast, Prof. Mark Ganter of the University of Washington (Seattle) described his students’ experiments in using “free” 3D printing materials, such as ceramic clay or even foodstuffs. Justin Rivera of Bell Helicopter Textron (Ft. Worth, Texas) revealed that his company uses AM to produce prototypes and replacement parts, and that Bell makes nearly 400 helicopter parts in this way.

Thomas Cender, from the University of Delaware, Center for Composite Materials (Newark, Del.), talked to a standing-room-only crowd about void reduction in out-of-autoclave (OOA) processing during part consolidation. His work focuses on the effects of compaction, hold time under pressure, airflow process modeling and air-bubble migration patterns. Christian Hopmann, from RWTH Aachen University (Aachen, Germany), presented intriguing data regarding the use of microencapsulated dyes in laminate structures as a means of damage detection. Dye-filled microcapsules are placed on a carrier veil under the top surface layer in a laminate structure. When the structure suffers an impact, the capsules break and, thus, “bruise” the surface of the composite part, betraying damage (or potential damage).

Dr. Byron Pipes of Purdue University, a featured lecturer, discussed how the material certification process might be accelerated through simulation tools that are developed and shared by both OEMs and the supplier community (read the two-part HPC series on this subject, writtem by Dr. Pipes and Rani Richardson (Dassault Systemes, Waltham Mass.) in “Accelerating the ..." and An Internet aid to ...." under Editor's Picks”).

Bill Pearson of North Sails (Milford, Conn.) spoke at the Awards Luncheon on Thursday about his company’s articulating and reconfigurable three-dimensional molds designed to enable fabrication of composite membranes with large surface areas, using robotic fiber placement. The strategies have broad implications for future, customizable design and manufacture in composites.

Standout papers included a presentation by Dr. Angelos Miaris of Premium AEROTEC GmbH (Bremen, Germany), a subsidiary of Airbus (Toulouse, France). He described the design and robotic manufacture of thousands of carbon fiber/PEEK thermoplastic laminate “clips” — parts that secure the Airbus A350 XWB’s composite skin panels to the aircraft’s network of fuselage frames and stringers. Wendy Lin, formerly principal engineer, composites, at GE Global Research (Niskayuna, N.Y.) and now a consulting engineer at GE Aviation (Cincinnati, Ohio), described the infusion of microcrack-resistant composites, using a nano-toughened, low-viscosity epoxy resin.

On the show floor, Laser Projection Technologies Inc. (Londonderry, N.H.) discussed its LPT 100 Projector, which integrates high-speed, laser radar with a 3D laser projection system. Launched in 2013, the system reportedly can be used for process control and verification as well as reverse engineering. According to company president Steve Kaufman, the system also can be set up for in-process inspection and feature recognition in automated processes: “Our system can measure the angle of a fabric and even individual tows to very high accuracy.” The LPT 100 measures at 100MHz/second and creates a 3-D point cloud of the measured surface. When it is combined with the company’s TOPO software, the LPT 100 visualizes production errors in the form of a topographical projection.

First-time exhibitor Nucap Industries Inc. (Toronto, Ontario, Canada), reportedly the world’s largest producer of metallic brake system components, was on hand to gauge interest within the composites industry for its new product called NRX, a metallic sheet or strip treated mechanically to form thousands of tiny raised projections or hooks. The hooks can be created on nearly any type of metal, and sheets can be as thin as 0.3 mm/0.118 inch. The hooks and the formable metallic sheet could be used to create hybrid metal/composite solutions, says Nucap’s chief operating officer Montu Khokhar.

BondTech Corp. (Somerset, Ky.), a specialist in autoclave system design and manufacture, revealed that the Long Island Forum for Technology (LIFT) consortium, headquartered in Bethpage, N.Y., has selected Bondtech autoclaves for LIFT’s Composites Prototyping Center (CPC), expected to become the center of a composites cluster on Long Island. CNC machining center manufacturer Quintax (Stow, Ohio), part of Stow-based Ferry Industries Inc., announced at the show that it has launched a redesigned Web site, for greater functionality and resource access for its customers.

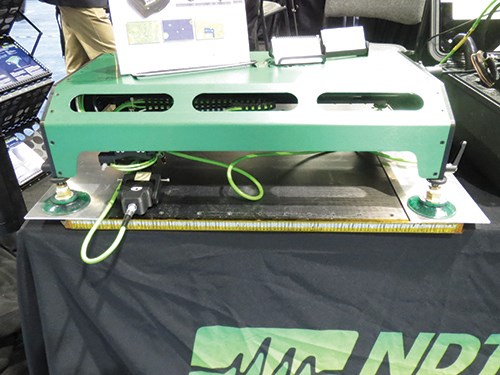

NDT Systems Inc. (Huntington Beach, Calif.) introduced at the event an automated C-scan-type imaging system called TunnelScan, for use in composites manufacturing and repair applications. Designed to work with the company’s Raptor imaging flaw detector, this dry, low-frequency scanner can be used to inspect foam cores, sandwich structures and traditional laminates, checking for disbond, delamination, crushed core and far-side defects. TunnelScan comprises an automatic X-Y scanner on a 12- by 18-inch (300 by 460 mm) bed that is attached to the part by magnetic or suction-type feet, prior to scanning. Also new from NDT Systems is BondHub, a bond testing C-scan device that captures images in resonance, pitch-catch or mechanical impedance modes. The portable, battery-operated unit is compatible with the company’s Bondascope 3100 system.

In the SAMPE Student Bridge Competition, held each spring, the winners were:

- I-beam carbon and/or aramid fiber, 7,000 lbf: U. of Delaware, Tongji University, U. of Washington

- I-beam glass fiber, 7,000 lbf: Tongji University, Cal Poly San Luis Obispo, U. of Delaware

- I-beam natural fiber, 3,000 lbf: Tongji University, U. of Delaware, Cal Poly San Luis Obispo

- Square beam carbon and/or aramid fiber, 10,000 lbf: U. of Washington, Harbin Engineering University, Cerritos College

- Square beam glass fiber, 7,000 lbf: Tongji University, U. of Washington, Harbin Engineering University

- Square beam natural fiber, 3,000 lbf: Tongji University, Harbin Engineering University, U. of Delaware

- Open design, 15,000 lbf: U. of Washington, Cerritos College, Harbin Engineering University

- Poster: McGill University, U. of Delaware, U. of Delaware.

The spring SAMPE conference will move across the U.S. map to Baltimore, Md., in 2015, followed by return west, to Long Beach, Calif., in 2016, and a stop in Salt Lake City, Utah, in 2017

FARO Technologies Inc.

Grip Metal

Institute of Plastics Processing (IKV) at RWTH Aachen University

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

BMW Leipzig: The epicenter of i3 production

A glimpse into the inner workings of an automaker at the forefront of serial-production autocomposites.

Read MoreAccelerating the certification process for aerospace composites

Columnist Byron Pipes foresees the certification of simulation software in place of physical testing.

Read MoreAn Internet aid for acceleration of aerospace composites certification

Guest columnist Rani Richardson, a CATIA composites product specialist at Dassault Systèmes (Waltham, Mass.), proposes a way to speed certification of aerospace composites.

Read More