Prepregs

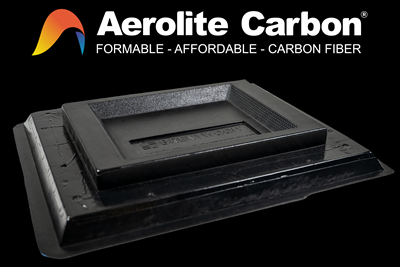

Westlake Plastics, Environmental Composites launch thermoformable carbon fiber composite

Aerolite Carbon is an advanced carbon fiber/thermoplastic material designed for fast, large-volume parts manufacture on existing equipment.

Read MoreRediscovering the benefits of prepregs in composites manufacturing

Compared to more traditional forms of composites manufacturing, prepregs enable reduced manufacturing costs and enhance production performance.

Read MoreSino Polymer develops high-performance epoxy resin systems for prepreg applications

The one-component carbon fiber prepreg can be cured at 150ºC for 10 minutes, is suitable for structural parts requiring Tg within 120-140ºC and can be stored for up to 18 months at -18ºC

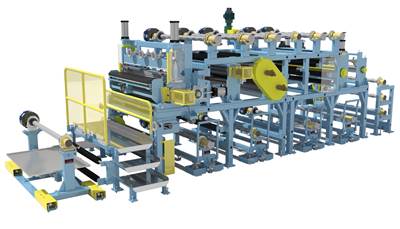

Read MoreEntry-level vertical prepreg treater

C. A. Litzler Co. Inc. offers an entry-level, solution-based vertical prepreg treater and hot melt horizontal coating line for the composites industry.

Read MoreTPRC investigates AFP in-situ consolidation alternative

The two-step process involves deposition of thermoplastic prepreg via AFP, followed by vacuum-bag-only (VBO). Research has already been completed in the qualitative stage.

Read MoreCAMX 2020 exhibit preview: Hexcel

Hexcel is showcasing its resins, thermoplastic UD tapes, epoxy prepregs and additive manufacturing technology.

Read MoreComposites complete IYRS heavy lift quadcopter demonstrator concept

Boasting a prepreg carbon fiber airframe, the HLAP concept became a platform for a variety of composite fabrication techniques.

Read MoreCAMX 2020 exhibit preview: DH Sutherland

DH Sutherland is introducing technologies for chemical application and the manufacture of protective armor.

Read MoreSky Advanced Materials fabrics win DNV-GL type approval

Certification for Hungary-based Sky Advanced Materials covers use of fabrics made with Zoltek PX35 50k tow carbon fiber combined with epoxy or vinyl ester.

Read MoreSino Polymer develops high-performance epoxy resin prepreg

Used in railway applications, the carbon fiber prepreg can be cured at 150℃ for 10 minutes, and is suitable for structural parts requiring Tg within 120-140℃.

Read More

.jpg;maxWidth=300;quality=90)