Entry-level vertical prepreg treater

C. A. Litzler Co. Inc. offers an entry-level, solution-based vertical prepreg treater and hot melt horizontal coating line for the composites industry.

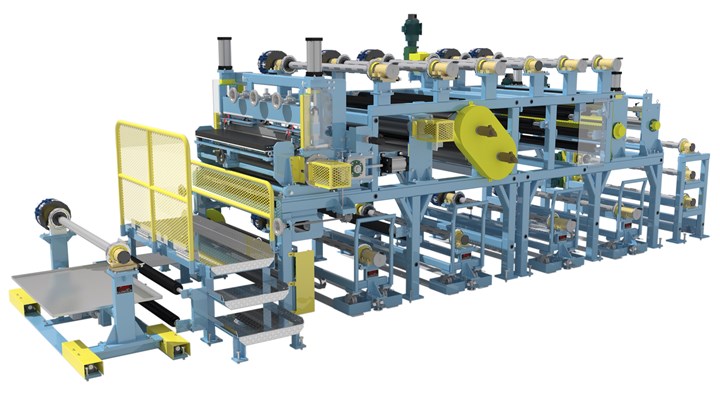

Hot Melt Adhesive Coater Filmer. Source | C.A. Litzler

C. A. Litzler Co. Inc. (Cleveland, Ohio, U.S.) offers an entry-level, solution-based vertical prepreg treater for the composites industry. The system is designed for unwinding, dipping, drying and winding of woven fabric under controlled conditions, and uses a smaller oven to provide a cost-effective, entry-level option. According to the company, Litzler ovens feature the company’s “Opti-flow” technology for uniform flow and temperature uniformity, especially side-to-side uniformity.

Litzler says it continues to expand its product line to meet demand for lower-cost prepregs in the automotive and aerospace markets. Other products and expertise include dryer technology, compaction rolls, tow spreading, and controls design and automation.

In addition, the company also offers a Hot Melt Adhesive Coater Filmer for special composites materials. The horizontal coating line is used to coat paper and fabrics for the composites industry.

System features include:

- Precision knife over roll filmer using the same style 0.0002" (0.005 mm) rollers as Litzler Compaction Rolls and Litzler Metering Rolls.

- Resin is fed from the top of the rolls and forms a dam — the web is fed through the precision knife gap to introduce the resin directly.

- Multiple unwinds, rewinds for scrim, paper and poly are said to make this a highly flexible machine for hot melt adhesives.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;width=70;height=70;mode=crop)