Prepregs

Hyperjoint: additive metal + composites = stronger, tougher joints

Eliminates drilling holes with lap shear 60% higher than bolted joints and almost twice that of bonded joints.

WatchPlant tour: Hexcel, Salt Lake City, Utah, U.S.

The scale, precision, speed and quality of carbon fiber manufacture has evolved substantially since the material’s modern introduction in the late 1960s. Hexcel offers a glimpse of the state of the art today.

Read MoreJEC Group announces 2020 Innovation Awards winners

The 13 winners were announced during a virtual ceremony on May 13.

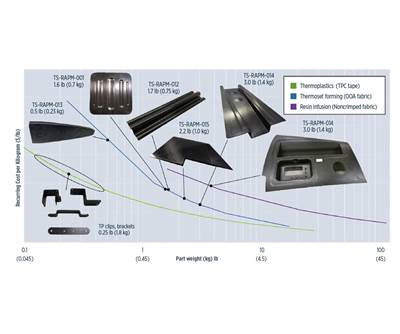

Read MoreRevolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

Read MoreHexcel HexPly M79 prepregs receive DNV GL Type Approval Certification

The new verification allows the materials to be used in all DNV GL classed vessels.

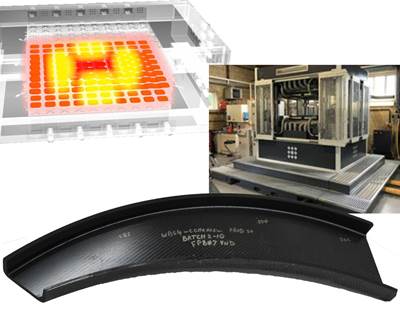

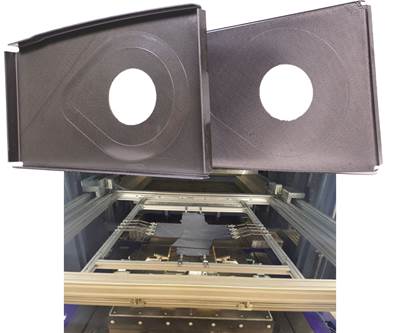

Read MoreRAPM development with PtFS

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

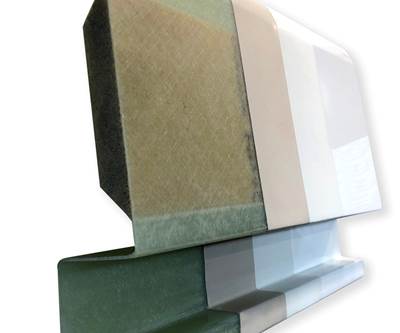

Read MoreNovel prepreg for compression molding in RAPM

Solvay and Boeing combine aerospace performance with process knowledge for high-rate, low-cost composites production.

WatchThird patent issued for flexible thermoplastic prepreg

Technology enabling wider tapes and easier weaving/braiding for void-free laminates now offered by Precept One LLC

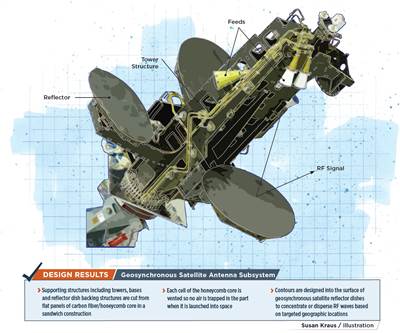

Read MoreTooling, precision enable composites in satellite subsystems

Tight tolerances drive design and engineering of large-format composite component and dishes to create unique satellite structures.

Read MoreCommercial-scale carbon fiber recycling comes to Tennessee

Accepting carbon fiber waste materials now, Carbon Fiber Recycling will recycle 2,000 tons of carbon fiber waste per year at its Tennessee facility.

Read More