Processes

Military base installs LEWCO composite curing oven

The oven has a maximum temperature of 650°F and is used to cure vacuum-bagged composite aircraft parts.

Read More9T Labs, ANSYS partner on composite design and simulation tools

A combination of software provides an integrated design and simulation workflow for 3D printing complex composite parts.

Read MoreSpirit AeroSystems opens new spoiler manufacturing facility

The Scotland-based facility will use advanced composites technology for high-volume production of spoilers for the Airbus A320 aircraft family.

Read MoreEPSRC Future Composites Manufacturing Research Hub announces two new core projects

Focused on design simulation for NCF preforming and tools for industrializing layer-by-layer curing, the projects will commence in May 2020 with university and industry partners.

Read MoreProving out LMPAEK welding for Multifunctional Fuselage Demonstrator

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test LMPAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

WatchJEC World 2020 preview: Trelleborg

Trelleborg Applied Technologies is showcasing advancements across its range of epoxy tooling boards.

Read MoreUsing mobile susceptors to innovate thermoplastic induction welding

IS Groupe and Arkema patent ISW for high-strength UD welds, temperature control and 50% less energy.

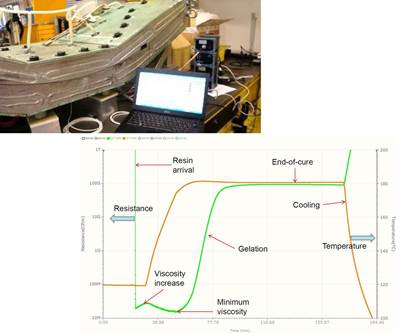

Read MoreDC dielectric sensors for industrial composites production

Synthesites in situ process monitoring enables cure decisions based on real-time Tg evaluation that can reduce cure cycles by up to 50%.

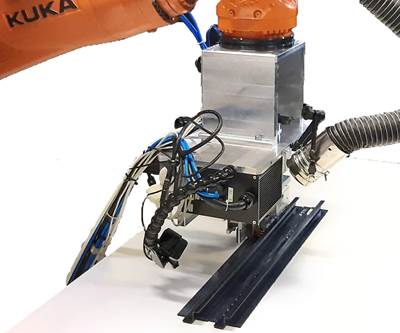

Read MoreIRT Jules Verne, Airbus and Fives launch MADRAS automated textile deposition line for WING project

Goal is full-scale testing of large, complex shape preforms at 5-6 times faster speeds for future aircraft.

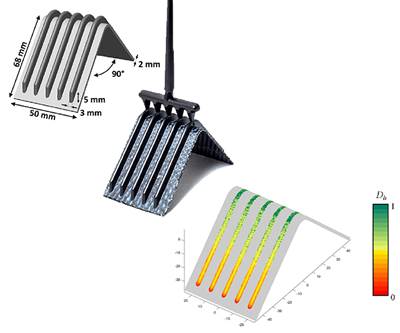

WatchNew research provides guidance for optimized thermoplastic composite overmolding

TPRC process modeling and testing of single- and dual-step processed parts points to optimum process conditions and improved design features.

Read More