9T Labs, ANSYS partner on composite design and simulation tools

A combination of software provides an integrated design and simulation workflow for 3D printing complex composite parts.

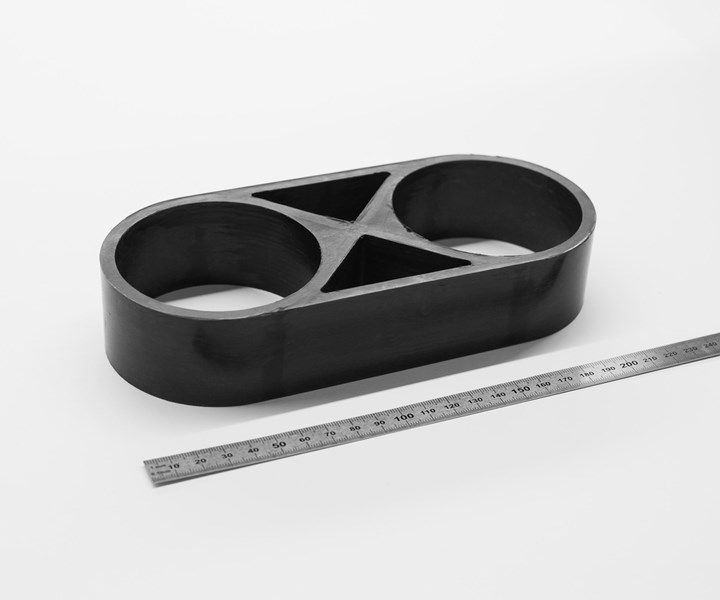

Final part manufactured by 9T Labs in collaboration with industry partner Setforge and Arts et Métiers Institute of Technology. Source | 9T Labs

9T Labs (Zurich, Switzerland) has partnered with engineering simulation company ANSYS (Canonsburg, Pa., U.S.) to provide an integrated design and simulation workflow for 3D printing of complex composite parts.

According to 9T Labs, as the deployment of 3D printers and tape laying machines increases, part complexity of composites rises simultaneously. Manufacturers aim to reduce production time, part weight, material waste and ultimately costs by challenging conventional geometries and fiber layups. The combination of both companies’ software solutions aims to give engineers the means to intuitively establish improved composite designs.

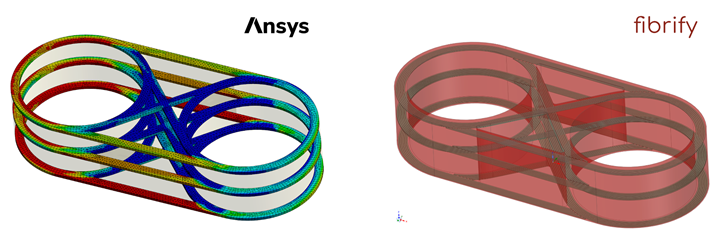

The partnership combines 9T Labs’ fibrify software and ANSYS’ Composite PrepPost (ACP), which enables users to create the lightweight parts without producing or testing them in advance. A new interface in ACP can directly import complex fiber layups established in fibrify and converts them automatically into a finite element model. Parts composed partially of neat plastic in addition to a fiber layup, such as for use in composite 3D printing, can also be simulated easily. According to 9T Labs, an optimal design can be found through an iterative process of geometry design and fiber layup composition in fibrify and running simulations through ACP.

9T Labs optimizes the design of the automotive bracket based on the simulation in ANSYS ACP. The most lightweight part can be reached by optimal fiber layup. Source | 9T Labs

Fibrify also enables users to connect to 9T Labs’ equipment, start production and monitor the process. In the Build Module, a preform is made after which the Fusion Module consolidates the part for end use in a structural application.

9T Labs and ANSYS plan to present this solution at JEC World in Paris from May 12-14. 9T Labs offers fibrify as part of its Red Series products, on order starting in March 2020.

In addition, 9T Labs is hosting a webinar on Thursday, March 5 to launch its Red Series technology. Register at app.livestorm.co/9t-labs/launch-red-series.

Related Content

-

Composite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

.jpg;width=70;height=70;mode=crop)