Processes

DHSutherland partners with KleanVak for promotion of surface preparation technology

DHSutherland will promote France-based KleanVak’s mold preparation and solvent cleaning technology to customers in the Americas.

WatchPresidium launches fast-cure, high-strength resin system

Presidium USA is introducing to the composites manufacturing market the RevoTherm line of resin systems that offer low viscosity, fast cure and high strength in finished parts.

Read More3D printing, composite materials enable motorsports design flexibility

A collegiate Formula SAE racing team used Windform carbon fiber-filled composite materials and laser sintering technology to streamline part design.

Read MoreAutomated system eliminates manual material pleating, cutting

AZCO Corp.’s custom cut-to-length system features a material flow package, pleating station and heat set station.

Read MoreJEC announces finalists for 2020 Innovation Awards

JEC Group has announced its JEC Innovation Awards finalists, 33 total from 11 categories. Winners will be announced at JEC World 2020 on March 4.

Read MoreCevotec, Fuji sign exclusive sales partnership for Japan and Thai markets

Japan-based Fuji Industries has exclusive rights to sell Cevotec products in the region, including Fiber Patch Placement composites automation technology.

Read MorePlant Tour: RUAG Space, Decatur, Alabama, U.S.

Out-of-autoclave composites manufacturing facility comes of age with first U.S.-made composite structures for the Atlas V launcher, and qualification parts for the Vulcan.

Read More9T Labs secures $4.3 million in funds to develop, scale-up continuous fiber 3D printing solution

The Swiss company has closed a seed financing round and added two additional industry veterans to its board of directors.

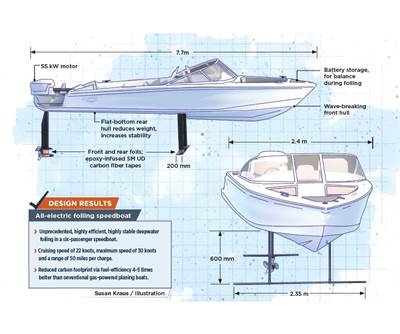

Read MoreComposites enable novel flying speedboat

Candela Boats’ Seven speedboat combines all-electric propulsion with precision foiling in a design made possible by creative composites engineering.

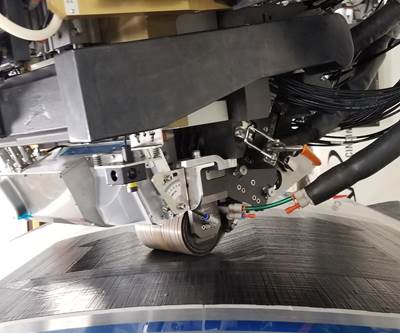

Read MoreCarbon ThreeSixty invests in Tailored Fiber Placement cell

The U.K.-based structural composites specialist says the automated cell delivers composite products three times faster, with up to 90% waste reduction.

Read More