9T Labs secures $4.3 million in funds to develop, scale-up continuous fiber 3D printing solution

The Swiss company has closed a seed financing round and added two additional industry veterans to its board of directors.

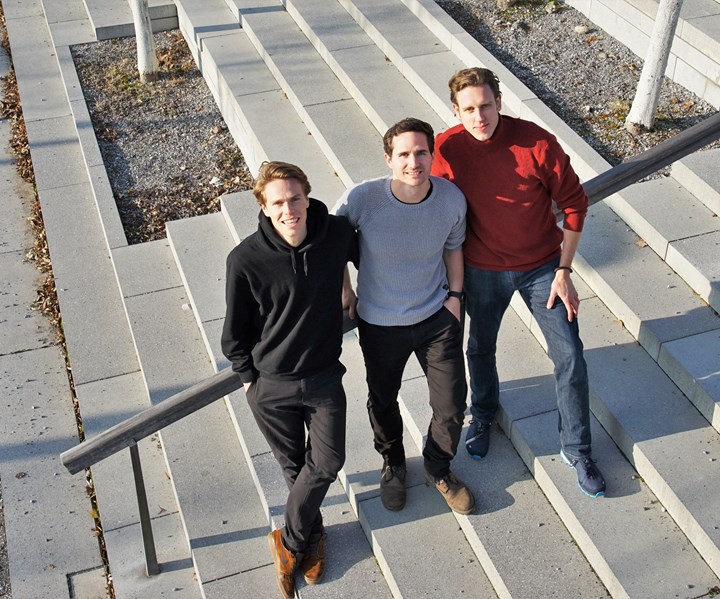

Source | 9T Labs

9T Labs (Zurich, Switzerland) has announced that it has closed a seed financing round of $4.3 million to finish the development of its industrial 3D printing solution and to scale-up the first mass manufacturing industrial use cases.

9T Labs’ proprietary technology combines advanced software algorithms, 3D printing technology and post-processing, and is offered as a solution to ease the use of industry-grade carbon fiber composites, driving down lead times and production costs to accelerate industry growth.

The company, which is a spin-off of ETH Zurich, was founded by Chester Houwink, Giovanni Cavolina and Martin Eichenhofer in 2018, with the goal of making carbon fiber composite materials as accessible as ordinary metal materials. The company has secured $4.3 million from existing investors around Wingman Ventures and new contributions from Investiere and the Technology Fund. Furthermore, 9T Labs is supported by the ESA BIC program.

Read more about 9T Labs and its continuous carbon fiber 3D printing technology.

In addition, as part of the financing round, Andreas Wuellner and Bertrand Humel van der Lee have joined the company’s board of directors, bringing together 40 years of experience in fiber composite processing and manufacturing. Until the end of 2019, Andreas led the composites business of SGL Carbon. Bertrand Humel van der Lee is an expert in sales, services and marketing related topics who was until recently chief customer operations officer and managing director at EOS.

“Knowing from experience what limits the widespread adoption of advanced fiber composite solutions, I found 9T Labs’ integral technology approach to overcome such limitations, fostering the adoption in mass manufacturing, very convincing,” Wuellner says.

“In contrast to plastic and metal 3D printing companies, which compete with the existing and established automated CNC manufacturing solutions, 9T Labs enters a market which has not yet seen standardized automation and software solutions for mass manufacturing, providing a huge market potential,” van der Lee says.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

.jpg;width=70;height=70;mode=crop)