Processes

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreUMaine’s novel polymer 3D printer surpasses former Guinness World Record

Four times larger than its 2019 predecessor, Factory of the Future 1.0 offers new opportunities in composite materials, including development of recycled and bio-based materials, opening up new research frontiers.

Read MoreDesigning an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

WatchFrom the CW Archives: The life and death of the BMW i3

A look back at the ambitious and impressive composites production system BMW developed for production of the all-electric i3 EV.

Read MoreVoxelMatters report reveals top companies in composites AM

The new market study identifies key players in a $785 million global market that has grown by 21% year on year.

Read MoreBelotti, Cosberg partner for advanced automated assembly solutions

The Italy-based companies merge technological know-how to develop novel systems for the processing and assembly of light alloys and carbon fiber components.

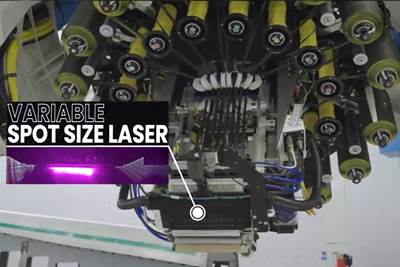

Read MoreElectroimpact offers variable spot size laser AFP 4.0 technology

Patented process technology increases quality, reliability and machine utilization for composite laminate production.

Read MoreOptimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

WatchILAuNCH Trailblazer project to use AM technologies to produce large-scale composite rockets

ILAuNCH partnership, joined by ANU and New Frontier Technologies, will develop a qualified manufacturing process that will directly contribute to the development of launch vehicle development.

Read MoreMaterialise adds three materials to enhance industrial 3D printing

Materialise expands additive manufacturing portfolio with early adoption of new HP PA 12S and integration of PA 11 and PA-CF materials.

Read More