Processes

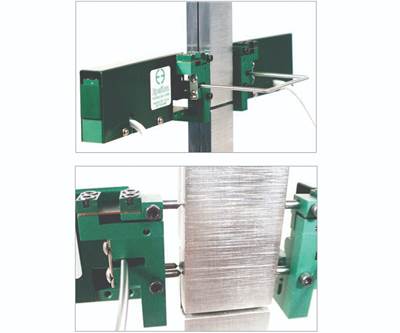

Application of video extensometry to ASTM D 5656

Reliable, reproducible data is central to the design and delivery of cost-effective bonded assemblies.

Read MoreConsolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

Read MoreJEC World 2018 preview: A. Schulman

New LYTEX SF epoxy-based, styrene-free, sheet molding compound

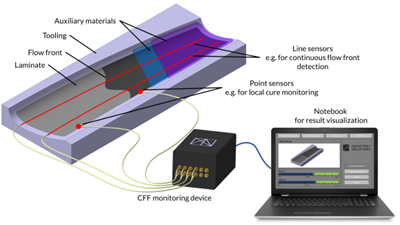

Read MoreSensors for monitoring resin infusion flow front and cure

InFactory Solutions commercializes technology to provide real-time resin impregnation and cure data across composite parts for zero-defect, intelligent process chains.

Read MoreJEC World 2018 preview: CHOMARAT

CHOMARAT unveils its new multiaxial NCF reinforcement for thermoplastics, plus an innovative UD carbon reinforcement for wind blades

Read MoreTechsil acrylate-based adhesive cures via light

Distributor Techsil (Bidford-on-Avon, UK) has introduced a new light-curing adhesive called Vitralit UV 4802, for bonding high-temperature-resistant thermoplastics such as PEEK with other non-compatible materials.

Read MoreCENIT presents initial results for bionic aircraft design project

CENIT reports development of CAD design tool for automated generation of bionic components and output for additive manufacturing.

Read MoreComposites give shape to new passenger bus

The VDL Bus & Coach Citea bus features composite structures fabricated using a vacuum expansion process (VEX) with specially formulated foaming resin compounds supplied by BÜFA Composite Systems.

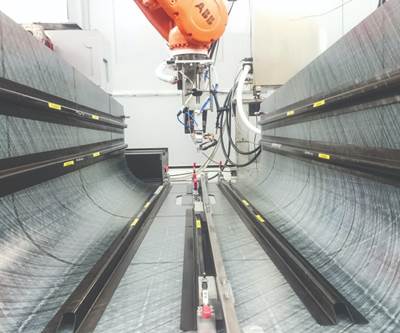

WatchSafran and Albany inaugurate new LEAP engine fan blade plant

The Mexico facility is the two companies’ third joint manufacturing plant to make composite parts for the LEAP aircraft engine.

Read MoreAirborne, Siemens and SABIC partner to mass produce thermoplastic composites

Flexible, automated production lines, featuring radically low conversion costs, aimed at millions of parts/yr — CW’s interview with all three companies.

Watch