Processes

3D-printed composite wind blades and aircraft, closer than you think

Orbital Composites’ patented coaxial extrusion process is investigated at Airbus subsidiary CTC GmbH Stade and spins off advances in speed, scale, materials and multifunctionality as it aims for very large structures.

Read MoreOvermolding as enabler for composites, aerospace to automotive

CCP Gransden can make 50 to 100,000 parts/yr economically viable using PEEK, PPS, PEI or PA.

Read MoreCevotec dry-fiber bindered tape available for automated placement

Manufacturer of SAMBA automated placement systems offers high-quality material aimed to make series CFRP production economical for non-aerospace applications.

Read MoreKraussMaffei opens second R&D pultrusion line

KraussMaffei’s TechCenter in Munich now features two pultrusion lines, one to fabricate rebar and the other to fabricate flat profiles.

Read More3D printing helps Latécoère cut lead times

Latécoère is deploying Stratasys FDM additive manufacturing throughout its design and production process.

Read MoreCPIC develops family of unique fiberglass products

CPIC has developed a family of unique fiberglass products with a flat rather than round cross-section that facilitates higher fiber loading levels and better mechanical properties in injection-molded thermoplastic composites while reducing warpage in thin wall sections.

Read MoreFold-to-form CFRP battery boxes, HP-RTM wishbones

Williams new EV platform demos 223 composite forming process and £20 suspension arms using recycled carbon fiber.

WatchChocolate Factory replaces metal parts with Stratasys composite 3D printing material

3D printed replacement machine part, produced in Stratasys FDM Nylon 12CF thermoplastic containing 35% chopped carbon fiber.

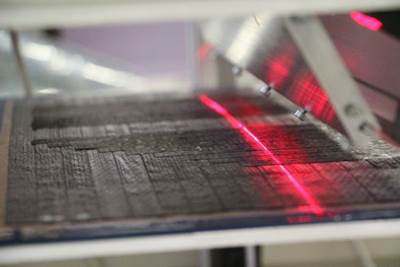

Read MoreZero-defect manufacturing of composite parts

ZAero project aims for 30-50% boost in productivity via inline AFP inspection, simulated part performance and decision support tools.

WatchSolvay to supply materials for the 777X program

Solvay will supply a range of material technologies including out-of-autoclave structural carbon fiber epoxy prepreg, flame resistant interior phenolic prepreg, lightning strike protection surfacing film and structural bonding adhesive.

Read More