Processes

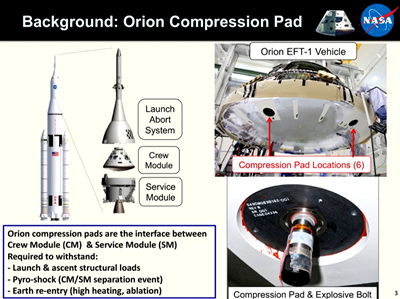

Bally Ribbons 3DMAT quartz composite is adopted for future NASA space missions

Named the NASA Government Invention of the Year, the 3D orthogonally woven materials supports structural and thermal performance needs for Orion mission and more.

Read MoreATL Composites collaboration advances kite-foil board production for Paris Olympics

Breiana Whitehead, pioneering Australian kite-foil sailor, spearheads board design intricacies with ATL Composites to enhance her performance ahead of the July 2024 competition.

Read MoreCalifornia grant extends affordable, 3D-printed housing efforts by Mighty Buildings

Three prefabricated, low-carbon homes, using Mighty Buildings’ large-format 3D printing and UV-curable resins, will be built in the San Francisco Bay Area as models for future industry developments.

Read MoreMechnano, Bomar introduce T50B low-viscosity masterbatch for 3D resins

T50B masterbatch by Mechnano, in partnership with Bomar, streamlines AM resin development, resolving CNT dispersion issues and elevating mechanical performance while catering to various printing technologies

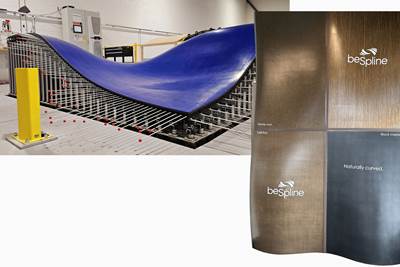

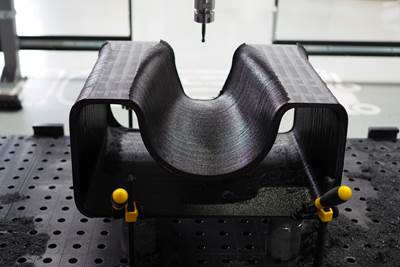

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreENRX, Roctool collaborate to advance mold electrification

Plastics and composites manufacturers will benefit from Roctool’s heat and cooling induction for molding processes, with increased technical service support and capability demonstrations on a global scale.

Read MoreManufacturing tech for scalable Type V hydrogen tank fabrication, CFRP lifecycle management

Cygnet Texkimp’s Multi Roll Stack and composite recycling technology catalyze ASCEND program’s mission to optimize aerospace, automotive hydrogen storage and CFRP sustainability.

Read MoreAl Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

Read MoreTGS to leverage CEAD Flexbot 3D printer for Czech Republic customers

The novel large-format Flexbot Research XL platform enables TGS to offer 3D printing services, making use of a versatile composite material range.

Read MoreMulti-material, self-sensing, 3D-printed scoliosis braces

Startup Fited and Brightlands Materials Center have developed a lighter weight, thinner CFRP corrective brace, including pressure sensors made from continuous carbon fibers.

Watch