Processes

DOE funds project for 3D-printed wind blade tooling

Targeting U.S. wind energy, the program backs Purdue’s CMSC center and industry partners to develop the foundation for automated tooling manufacture, supporting new innovations in composite materials, other technology elements.

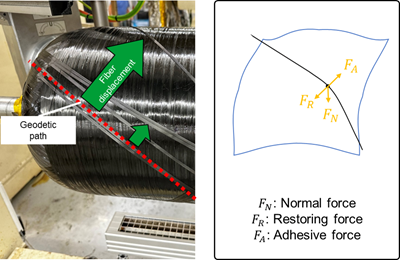

Read MoreIVW research to better determines fiber friction coefficient

Highly variable system development contributes to the increasing precision and efficiency in the manufacture of filament-wound composite components.

Read MoreAbaris selects Premier ESR to optimize composite cure cycles

Encapsulated sample rheometer (ESR) by Alpha Technologies will be incorporated into Abaris’ service and consultation business to characterize a variety of composite material specimens.

Read MoreCompcut features ACS, PCR composite cutting technologies

Advanced plate saw and precision router provide precise, fast and efficient cutting of composite test specimens.

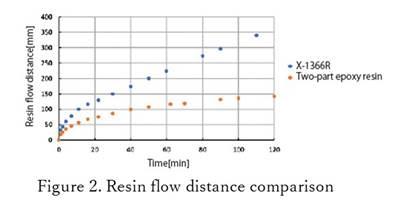

Read MoreMatsumoto Fine Chemical unveils solution for efficient infusion process with one-part epoxy resins

New one-part epoxy resin X-1366R shows very low viscosity and can be easily impregnated to reinforcing fibers at room temperature without resin/hardener mixing process.

Read MoreSiemens and Electroimpact highlight capabilities of SCRAM continuous fiber 3D printing system

The scalable robotic additive manufacturing (SCRAM) six-axis, continuous fiber 3D printing system combines multiple processes in one cell, powered by a Siemens control platform.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreORNL conducts sustainability analysis of 3D-printed composite molds

A comprehensive lifecycle, cost and carbon emissions study on carbon fiber molds, produced for New York’s concrete Domino building, cites economic benefits over wood alternatives.

Read MoreEngine vane demonstrates potential for gapped, unidirectional dry fiber for infusion

GKN Aerospace and its partners developed an aircraft demonstrator component made with TeXtreme’s latest Gapped UD material, proving out a dry, infusible tape meant to compare in performance to UD prepreg.

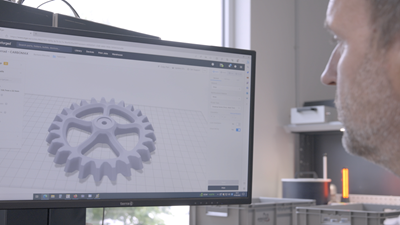

WatchMarkforged introduces Digital Source platform for manufacturer-certified parts

Digital Source aims to solve supply chain challenges with licensed, digital inventory printed through Markforged’s global 3D printer network at the point of need.

Read More