Processes

Evonik, Lehvoss launch fiber-reinforced polyamide for SLS

Collaboratively, Lehvoss has developed Luvosint PA613 9711 CF, which is capable of being processed via standard laser sintering machines.

Read MoreBMComposites, Linx Tenders use composites to lighten foiling cats

Glass and carbon fiber meet performance needs for custom-built tenders.

Read MoreCTC commissions Carbon Axis XCell machine for LaiLa project

The XCell AFP machine is being used to investigate innovative fiber deposition concepts and improve lightweight production via Industry 4.0.

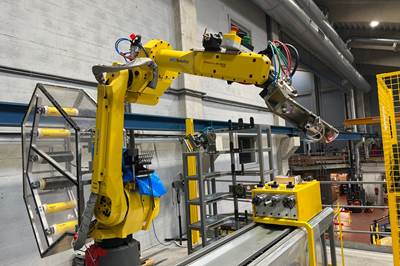

Read MoreCompoTech promotes automated filament winding machine options

Custom-built, turnkey automated winding and filament placement equipment create new possibilities for manufacturers to cost-effectively produce high-strength structural carbon fiber components.

Read MoreFives introduces COAST in-process composite inspection technology

COAST is capable of precise measurement and defect detection on contoured composite surfaces during the AFP process, reducing costs and increasing AFP accessibility.

Read MoreMikrosam filament production line supports Amargo tank production

Mikrosam system features will support the production of Amargo’s chemically resistant pressure vessels or hydrogen storage in industrial plants.

Read MoreRaise3D composite 3D printers feature open material platform

The RMF500 and E2CF 3D systems are equipped with enhancements to ensure precise and reliable handling of multiple chopped fiber filaments, polymers.

Read MoreBeSpline wins IBEX Innovation Award, announces partnership with Boston Boatworks for Shaped Foam Kits

CAD-driven fabrication uses adaptive mold technology for lighter, stronger, higher quality boat structures without time and cost of building a mold while drastically reducing core fitting time for yacht builders.

Read MoreSolvay expands range of FusePly covalent bonding for composite structures

FusePly 250 technology, designed for 250°F to 350°F composite bonding, offers optimized bond reliability and high part performance.

Read MoreComposite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Read More