Processes

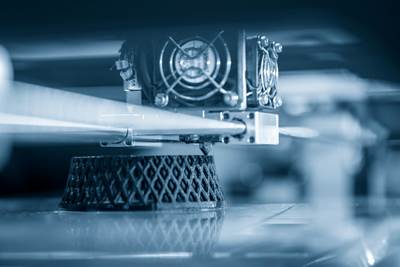

Increased molding productivity via additive manufacturing

Companies in multiple segments turn to 3D printing for end-of-arm tools, fixtures for increased safety and functionality, lower cost and faster turnaround times.

Read MoreAirtech launches recycled-grade Dahltram T-100GF resin

Thermoplastic polymer resin was designed to tackle distinctive industry challenges of large-scale 3D printing while also assisting with sustainability initiatives.

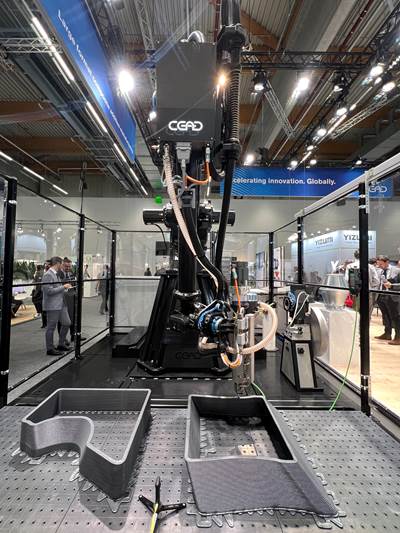

Read MoreAirtech Advanced Materials Group partners with CEAD

The partnership enables Airtech Advanced Materials Group to incorporate CEAD Flexbot systems into its advanced manufacturing portfolio.

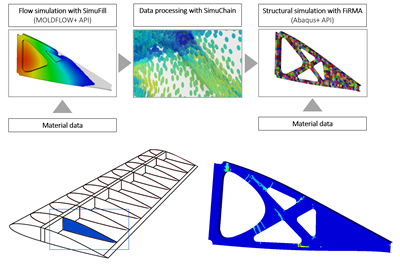

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

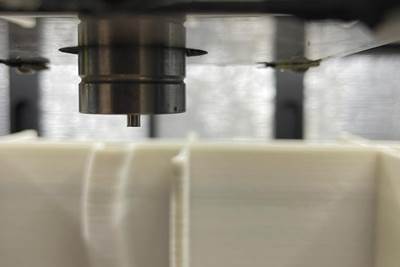

WatchMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

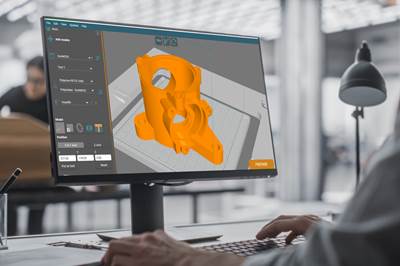

WatchAIM3D's Voxelfill strategy is backed by slicing software SlicEx

New slicing plug-in from Create it Real for AIM3D’s Voxelfill technology to overcome inhomogeneous strengths and to achieve selective densities of 3D metal, fiber-filled plastic and ceramic components

Read MoreCEAD solidifies U.S. presence with new Michigan location

CEAD Group Inc. marks global expansion of the company’s advanced 3D printing technology solutions, enhancing local client support and enabling new industry collaborations.

Read MoreXenia Materials reveals composite materials for FDM printing

A new range of 3D printing materials are formulated for use on any pellet-based fused deposition modeling printer.

Read MoreAON3D introduces high-temperature 3D printer, software platform

The Hylo “smart” printer and accompanying Basis software simplify and expedite the printing of open market materials, fiber-reinforced composites and polymers.

Read MoreEvonik, Lehvoss launch fiber-reinforced polyamide for SLS

Collaboratively, Lehvoss has developed Luvosint PA613 9711 CF, which is capable of being processed via standard laser sintering machines.

Read More

.jpg;maxWidth=300;quality=90)