Processes

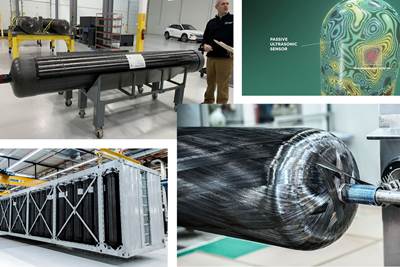

Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

WatchPEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

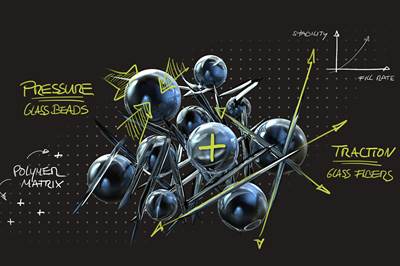

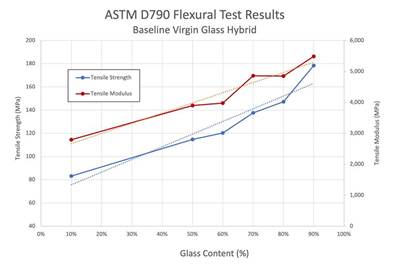

Read MoreSwarco glass filler beads enable 3D printing material optimization

A range of tailor-made glass filler beads for additive manufacturing help improve the properties of 3D printing base materials, including composites.

Read MorePilot program turns EOL wind blades to liners for pipe infrastructure

TPI Composites, Tex-Tech and Carbon Rivers partner to process wind blades, pyrolyze the material and use the recovered glass fibers to give new life to damaged existing pipelines.

Read MoreCompPair adapts HealTech composites to LCM processes

The new system, demonstrated through the manufacture of a large-scale wind turbine blade section, enables the repair and recovery of infused composite structures within minutes.

Read MoreWindform LX 3.0 composites contribute to OreSat0 CubeSat deployment

Portland State Aerospace Society, incorporating CRP Technology’s GFRP composite materials and SLS 3D printing, sent its CubeSat nanosatellite into low Earth orbit in 2021, where it continues to operate successfully.

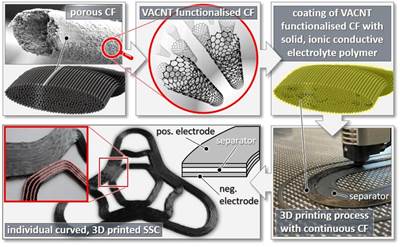

Read MoreRCCF of TU Dresden develops next-gen, 3D-printed structural supercapacitors

Thales Research and Technology leads PRINTCAP project for more sustainable fast-charging, structural energy storage for automotive and aerospace industries using multifunctional composite materials

Read MoreC.R. Onsrud breaks ground for machine shop expansion

Multi-phase expansion includes 9,900-square-foot addition to facility and purchase of new equipment to better serve aerospace, marine, composites and other industries.

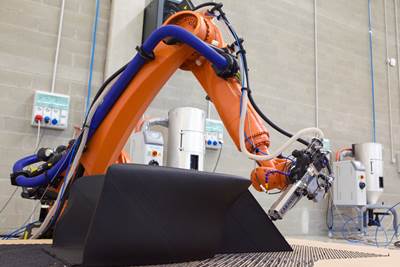

Read MoreCaracol scales up, expands internationally with €10.6 million Series A funding

Development and commercialization of Caracol’s turnkey large-format 3D printing platform Heron AM, and new hubs in North America and Middle East solidify the company’s swift growth.

Read MoreEUVAM project investigates energy-efficient UV process for composites curing

University of Stuttgart researchers intend to develop flexible, highly productive and digitally controllable manufacturing approach for small urban vehicle production.

Read More