Processes

Mighty Buildings opens new factory in Monterrey, Mexico

Company takes next step in strategy to scale rapid development and construction of 3D-printed, climate-resilient, carbon-neutral homes leveraged by patented composite materials.

Read MoreAnisoprint expands global presence with Shanghai office

New office located in the Additive Manufacturing Technology Centre enables Anisoprint’s expansion into the Asia-Pacific region.

Read MoreJabil, KAV Sports deliver customized composite bike helmets

Innovative materials science and 3D printing collaboration meets stringent criteria, enables mass customization for consumers.

Read MoreGMI Aero extends Anita EZ hot bonder thermocouple capabilities

Thirty-six thermocouples (T/Cs) are now available for flexible temperature monitoring/control during composite curing.

Read MoreSABIC debuts EN45545 rail-compliant, fiber-reinforced compound

LNP Thermocomp AM DC0041XA51 offers the rail industry a solution that can be used for on-demand printing of large, complex exterior and interior parts in relatively small build numbers.

Read MoreDemonstrating functionalized, cost-effective composites using additive extrusion

Hybrid thermoset/thermoplastic composite part with 3D-printed functionalization demonstrates technology possibilities and EmpowerAX open platform offering expertise from members throughout the process chain.

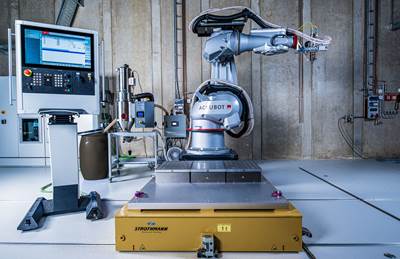

WatchMachina Labs awarded contract for robotic composites manufacturing

The initiative, enabled by the U.S. Air Force, is designed to advance metal tooling for high-rate production of composites.

Read MoreAptco Technologies supports supply of Compcut cutting machines

The pan-European partner to Sharp & Tappin will actively promote, sell and support the composite cutting solution to meet rising demand across Europe.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreAIM3D, Naddcon implement digital process chain for 3D printing

The ExAM 255 multi-material 3D printer from AIM3D, integrated into Siemens’ NX design software, opens up new optimization possibilities for 3D-printed designs, demoed by a 3D-printed GFRP component.

Read More