Processes

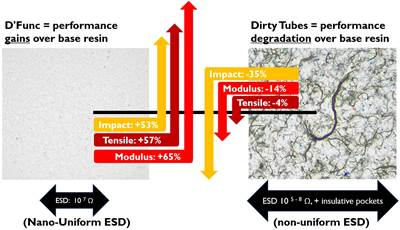

Mechnano trademarks CNT dispersion process for AM materials

D’Func dispersions eliminate clumped and roped CNTs, leading to increased electrical and mechanical performance in 3D-printed parts.

Read MoreXlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

Read MoreOrbital Composites licenses AMCM technology

Additive manufacturing compression molding (AMCM), co-developed with ORNL, combines robotic AM and continuous fiber technologies to revolutionize high-volume composites manufacturing.

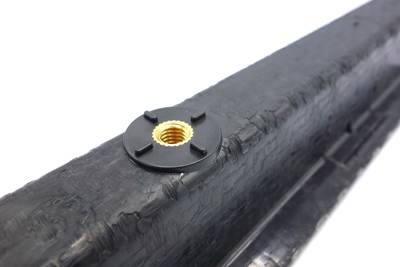

Read MoreExel Composites pultruded rods enhance Umbrosa parasol durability

The Belgium-based manufacturer chose pultruded fiberglass ribs for many of its umbrella and parasol designs to effectively endure exposure to high wind speeds, saltwater, rain and UV.

Read MoreLoop Technology robotic machining system works with harder materials

The RoboMach HA is a high-accuracy robotic machining system that can work with a range of materials, including cured composites.

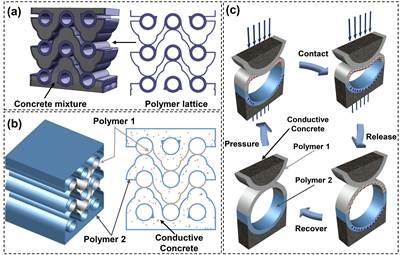

Read More21st century concrete: composite metamaterial with super compressability, energy harvesting

Material comprising 3D-printed, auxetic, reinforced polymer lattices in conductive cement matrix can compress up to 15% and generate electricity for lightweight, mechanically tunable structures with energy harvesting and sensing.

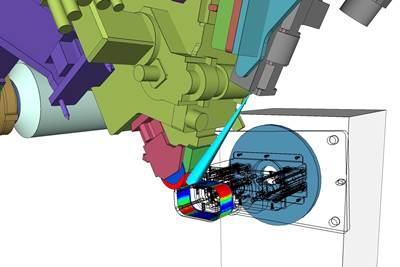

Read MoreHeat mapping simulation to improve AFP parts

An optical model developed for Coriolis Composites’ SimuReal AFP process simulation software enables verification of energy distributions during AFP to better define heating laws.

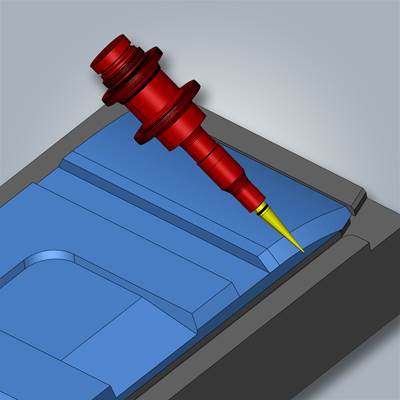

Read MoreOpen Mind Technologies leverages ultrasonic knife cutting strategy for composites

HyperMill from Open Mind Technologies utilizes CAM software for ultrasonic knife cutting strategy.

Read MoreGerman consortium develops biopolymer-based Cellun composite

German Institutes of Textile and Fiber Research (DITF) and partners present a conventional composite material alternative using cellulose that can be processed using industrial processing methods.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read More