Processes

Anisoprint, Bosch Rexroth join forces for industrial continuous fiber AM capabilities

Anisoprint’s first generation of industrial printers, PROM IS 500, is powered by Bosch Rexroth’s MTX, a tried-and-proven CNC system for industrial 3D printing technologies.

Read MoreiPul pultrusion system enhances Carbon TT’s CFRP profile production for vehicle chassis

Krauss Maffei’s subsidiary, Pultrex, delivers a customized iPul pultrusion system for the production of large profile parts for around 70,000 vehicle chassis annually.

Read MoreMikrosam celebrates commissioning of world's largest production line for CNG and hydrogen tanks

Turnkey project integrates four filament winding machines, two large ovens and multiple robotic lines and buffering stations to produce 60,000 tanks per year.

WatchRiding pretty: Hybrid upper control arms move to pickups

Short-glass/PA6 with metallic inserts reduces mass, running torque, joint wear on the Ram 1500 half-ton pickup truck.

Read MoreExel Composites, Keneco Group establish joint venture for pultruded composites solutions

Kineco Exel Composites India is a composites design, engineering and production company based in Goa, India, which will serve the Indian market across transportation, wind power, infrastructure, telecommunications, aerospace and defense markets.

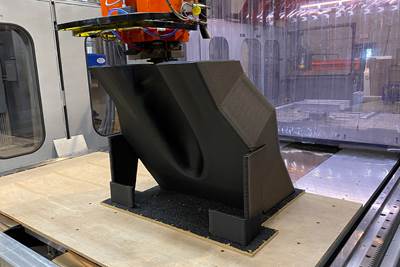

Read MoreCollaborative Boeing-led project validates large-scale composite AM tooling

The U.S. Navy-funded program demonstrated a large-scale, autoclave-curable 3D-printed carbon fiber composite tool using a Thermwood LSAM machine.

WatchArris Composites, Airbus collaborate on composites research for lightweighting cabin brackets

The project aims to demonstrate significant reductions in aviation emissions by leveraging topology optimization and advanced composites to replace metal brackets used on aircraft.

Read MoreSicomin infuses Couach's superyacht with bio-based epoxy resin

Sicomin’s InfuGreen 810 was used to vacuum infuse Couach’s 26-meter, 52-ton superyacht’s hull, deck and superstructure, for a lighter, faster, more durable yacht.

Read MoreMiddle River Aerostructure Systems expands MRO capabilities for jet engine nacelles

A dedicated, 60,000-square-foot MRO workshop will accommodate the processing of large nacelles and thrust reversers, including complex composite and metallic repairs, and bonding.

Read MoreCarbon fiber, additive manufacturing enhance Pleko spike shoe performance

Developed with 3D scanning support from Diadora and CRP Technology’s Windform SP carbon fiber-filled composite material and 3D printing process for a track shoe that meets individuals’ needs in terms of foot structure and athletic performance.

Read More