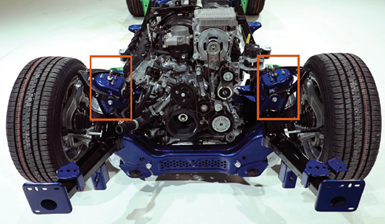

The 2019 Ram 1500 half-ton pickup from Stellantis was industry’s first use of a hybrid composite/metal upper control arm on a light truck. The innovative design reduces mass and lowers operating torque on the ball joint during operation. Photo Credit: Stellantis.

The automotive industry’s third hybrid (composite/metal) upper control arm with integral ball joint — and the first one on a light-duty truck — debuted on the 2019 model year (MY) Ram 1500 pickup from then Fiat Chrysler Automobiles (FCA, Auburn Hills, Mich., U.S., now Stellantis, which was formed earlier this year with the merger of FCA N.V. and Groupe PSA). In addition to providing the usual benefits that come with the use of composites, including mass reduction, parts consolidation, reduced secondary finishing and competitive cost versus conventional all-metal control arms, the innovative module also reduces running torque on the ball joint. This is the story of how composite/metal control arms have evolved.

Vital to a smooth ride

Integral to vehicle suspension systems for more than a century, control arms permit the up and down movement of a vehicle’s suspension while simultaneously connecting axles, wheel hubs and steering knuckles to each other and to the vehicle itself. Essentially, control arms allow the vehicle’s suspension system to flex in response to road conditions while also responding to steering input from the driver. They are considered vital to a comfortable, smooth ride. Some vehicles use one control arm per wheel and some use two (an upper and a lower).

Upper control arms typically have a wishbone (A-frame/A-arm) shape. Originally they were produced in stamped and welded steel, which was prone to corrosion. Next, they were produced in cast iron — especially for heavier pickups and sport utility vehicles (SUVs). Although very strong and more durable than stamped steel, they were quite heavy. More recently, control arms have been produced in cast aluminum, which is lighter than the ferrous metals and less prone to corrosion, but also more costly. Regardless of the material used for the upper control arm itself, they all are equipped with a ball joint on the wheel side of the vehicle and bushings on the frame.

The hybrid upper control arm technology was developed by the Chassis & Suspension division of Tier 1 Iljin Group (Seoul, South Korea). The company says it’s the world’s largest generation-three wheel bearing supplier with parts on approximately 40% of automotive platforms. In addition to supplying premium wheel bearings, the company also produces chassis, suspension and powertrain components for customers in the automotive (OEM and aftermarket), aviation, rail, off-highway and industrial market segments globally.

Generation one hybrid control arms: EVs

An interesting aspect of the hybrid control arm Iljin developed is that it incorporates an integral ball joint cap/cup that is formed during injection molding. In traditional metallic upper control arms, the ball joint cap/cup is a metal box welded to the control arm. Its purpose is to constrain side-to-side motion of the ball joint. However, that can lead to point stresses on the bearing/ball joint and higher torque during operation. That, in turn, can lead to more axial “end play” or “lash” (movement within the bearing housing/case), which can contribute to higher wear and operating noise, and can reduce service life.

To match steel performance requirements with the hybrid control arm, the team incorporated a steel reinforcement plate (overmolded during the forming process) and also used a heavily ribbed structure on the underside of the part. Photo Credit: Iljin Group

To match steel performance requirements with the hybrid control arm, the team incorporated a steel reinforcement plate (overmolded during the forming process) and also used a heavily ribbed structure on the underside of the part. Photo Credit: Iljin GroupIn contrast, with the hybrid system, the space between the pre-greased ball joint cap/cup and the bearing (both inserted prior to injection molding) is encapsulated with composite material during molding, eliminating the need for a welded swedge/box, since the ball joint is effectively cradled in the control arm. Any stresses that arise during operation are more evenly distributed, reducing operating torque on the ball joint and lowering end play and wear, which are expected to lead to longer service life for both the joint and the control arm. This aspect is an important benefit of the technology in addition to the opportunity to reduce weight and achieve a cost-competitive position versus traditional all-metal systems.

By the time Iljin’s North American team in Novi, Mich., U.S. began working with FCA’s engineering team on the Ram pickup, Iljin’s team in Korea had already developed the hybrid upper control arm for two electric vehicles (EVs) — one that had already launched and one that would launch during developments on the Ram pickup. Those platforms have since been joined by a third EV, which launched after the pickup.

There are several reasons why the hybrid control arm technology found its way onto electrified passenger cars before light trucks with conventional internal combustion engines (ICE). First, passenger cars are lighter weight, designed to carry considerably lighter loads and aren’t intended for off-roading, towing or other rough-duty usage as pickups are, meaning loads, durability and stiffness requirements were easier to meet.

Second, EVs are more weight sensitive, so automakers are more willing to pay a premium for mass reduction because the less the vehicle weighs, the greater the distance it can be driven on a single battery charge. This helps reduce range anxiety, which is the number one reason cited by consumers for not switching from conventional vehicles to EVs. Third, EVs are generally lower volume but higher cost than comparable-size ICE vehicles, making it less economically risky to try new technology, particularly when weight is saved at competitive cost.

Generation two hybrid control arms: Light trucks

“Although our plan was to offer similar driveline options as on the outgoing model, the new Ram 1500 half-ton pickup was designed to provide higher payload and towing capabilities — both of which impact overall chassis durability,” explains Phil Cataldo, Stellantis design responsible-body on frame suspension. “That meant we started this program having to solve a technical contradiction: engineer an increase in capability/durability, but at lower mass, which was not an easy task. That made it critical for Ram engineering teams to push for innovations like the hybrid control arm in order to meet or exceed system and vehicle weight targets.”

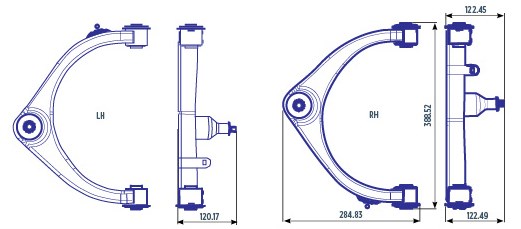

The final wishbone-shaped control arm is approximately 285 x 389 millimeters in size for left and right front wheels. Photo Credit: Iljin Group

“The significantly higher vehicle mass and concurrently higher loads and stiffness requirements of a light-duty truck meant that we had to meet far more challenging specs than on our previous EV programs,” adds Adam Herbolsheimer, Iljin North American sales director – chassis division. “Because this was the first time the technology had been tried on a light truck — and a flagship model at that — we had to meet the same performance requirements as the previous-generation control arm, which was a boxed section, steel-reinforced component. On top of that, our Iljin team had its own goal of reducing mass on the benchmark control arm weight by 15%.”

The material that had been used on the EV programs was Ultramid B3WG10 GF50, a 50% fiber weight fraction (FWF) injection moldable short-glass fiber/polyamide 6 (PA6) composite from BASF SE (Ludwigshafen, Germany). “This grade was selected for its toughness/impact strength, broad chemical resistance — especially to automotive fluids — and for having a coefficient of thermal expansion [CTE] close to that of steel,” notes Tushar Patel, BASF application development engineer. “The material also has a long history of use in other plastic/metal hybrid structures.”

Control arms permit up and down movement of a vehicle’s suspension and are vital to a comfortable ride. They also connect axle, wheel hubs and steering knuckles to each other and the vehicle frame. The new hybrid upper control arm on the Ram 1500 pickup reduced mass 13% versus the outgoing all-metal version while lowering operating torque on the ball joint. Photo Credit: Stellantis

However, to meet steel performance requirements for the new Ram pickup, the team made two changes that had not been featured on the earlier designs for the EVs. First, a steel reinforcement plate that was roughly the size of the control arm was added. Second, a lattice (heavily ribbed) structure was designed into the underside of the control arm. Fortunately, despite the high glass loading and numerous thickness transitions, the material fills intricate design features well. The single-cavity tool features two shutoff valves with a single hot runner, although the molder does not inject sequentially. The tool is manually loaded with the reinforcement plate and ball joint cap/stud prior to press closure and injection overmolding. Cycle time is roughly 50 seconds and close to 1 million parts are produced annually.

After passing all required testing by the Ram engineering team — including additional temperature cycling to ensure durability during real-world driving conditions — the new hybrid control arm went into production early in 2018 for the new 2019 model Ram pickup, reducing mass versus the outgoing fully metallic control arm by 13%. Since that time, the team has continued to work on making the hybrid control arm even more efficient by increasing rib depths, which permitted elimination of the steel reinforcing plate, reducing mass by an additional 4%. The hybrid upper control arm technology also has been translated onto the Jeep Grand Wagoneer SUV.

Related Content

Windform XT 2.0 IMG brings sustainability to injection molding

Carbon fiber-reinforced PA12 thermoplastic launched by CRP Technology is a 100% recycled high-performance material derived from the Top-Line range for 3D printing.

Read MoreBlueHalo launches next generation of Intense Eye UAS

Unmanned aerial system (UAS) from BlueHalo featuring an HX5 injection-molded chassis from Alpine Advanced Materials is said to be lighter, stronger and more efficient than aerospace-grade aluminum.

Read MoreXnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

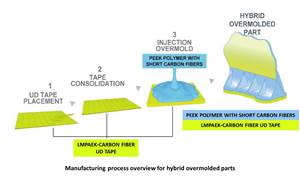

Read MoreTool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

Read MoreRead Next

Lanxess, INFAC develop composite battery module housing

The halogen-free, flame-retardant and glass fiber-reinforced polyamide 6 (PA6) part lowers battery module assembly weight, improves insulation and flame resistance and retains a high level of functional integration.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)