Processes

AON3D, Astrobotic to send 3D-printed parts to the moon

The Peregrine Lander will carry thermoplastic parts printed via AON3D’s high-temperature industrial 3D printer that meet demanding space requirements and cut the vehicle’s weight by half.

WatchLewco supplies custom composites curing ovens for aerospace

Lewco Inc. recently supplied ovens to three customers ranging from a research laboratory to an aircraft manufacturer.

Read MoreHarper International expands product offering with lab-scale rotary furnace

The furnace delivers temperature uniformity for batch or continuous processing of advanced materials at at operating temperatures up to 1,200°C.

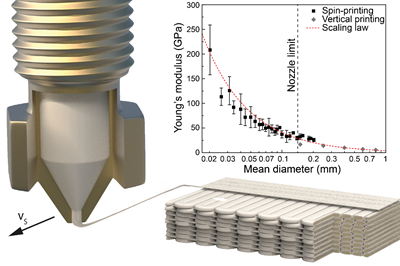

Read MoreResearchers develop liquid crystal polymer spin-printing process for recyclable composites

ETH Zürich, TU Delft and EMPA simultaneously 3D prints parts with spun fiber reinforcement for stronger, more sustainable, fully recyclable components.

Watch3M announces its enhanced 3M Scotch-Weld Structural Acrylic Adhesives portfolio

New offerings include low odor, enhanced performance, high elongation and nylon bonding capabilities.

Read MoreRECONTRAS project validates use of microwaves and laser welding to obtain recyclable composites

Reseachers obtained a reduction in costs and energy consumption through the manufacture of three composite prototypes and confirm the feasibility of recycling and processing the resulting material.

Read MoreHexcel, HP Composites develop carbon fiber Class A body panels

Italian component producer combines composites processing expertise with Hexcel HexPly XF3 surfacing material, HexPly M47 and HexPly M49 prepregs for supersport sedan external body panels.

Read MoreRefrigerated railcar floor expands composites horizons

TrinityRail, in an effort to update a 20-year-old design, seizes the opportunity to apply composites in a structural application in its refrigerated railcar. It’s a first for the rail and composites industry.

Read MoreIncreasing the composite stack: Co-molding of dissimilar materials

This demo introduces the concept of co-molding with thermoset composites to improve the final part performance. (Sponsored)

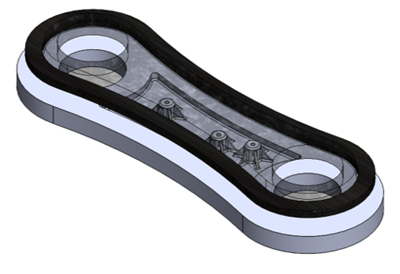

WatchCosiMo: Smart thermoplastic RTM process demonstrated for battery box cover challenge simulator

Project uses network of DEA, temperature/pressure and ultrasonic sensors plus digital simulation and AI modeling to monitor and optimize injection of caprolactam into complex glass fiber preform and in-situ polymerization of PA6.

Watch