Processes

TPS ships Gruenberg vertical conveyor oven, meets specific customer needs

Stainless steel internal chamber, operating temperature of 270ºF and an installed high-volume, 6135 CFM horizontal airflow system.

Read MoreMarkforged goes public with merger to one

The 3D printer company’s merger with special-purpose acquisitions company (SPAC) one is expected to close in summer 2021.

Read MoreDLR launches EmpowerAX to industrialize continuous fiber 3D printing

Global, industry-diversified platform will increase access to additive extrusion (AX) technologies and accelerate technology transfer for users and providers.

Read MoreStratasys carbon fiber material for 3D printer line is more functional, lightweight and versatile

ABS-based carbon fiber material for the Stratasys F123 Series 3D printer line is 15% stronger and 50% stiffer compared to standard ABS.

Read MoreTow steering, Part 3: The birth of tow shearing

In-plane shearing of tows, versus in-plane bending of tows, hopes to take automated fiber placement directionality to new levels.

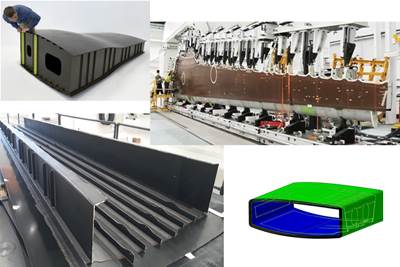

Read MoreAdvancing the OOA infused wing box

MTorres integrates lower cover, front and rear spars into unitized flying demonstrator using one-shot, low-cost, portable production.

Read MoreThe path to OOA wings with minimal fasteners

A review of the quest to eliminate both the autoclave and mechanical fasteners in composite wing structures.

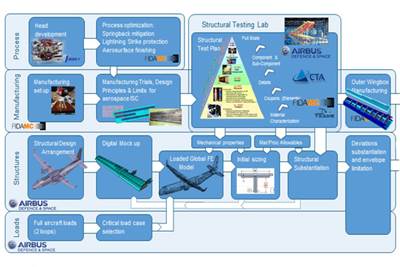

WatchIIAMS wing box road map to certification

Airbus DS uses Clean Sky demonstrators as part of broad strategy to ready next-gen aircraft technology for flight.

Read MoreHexPly XF surface materials satisfy high-quality wind blade surface finish

Suitable for prepreg and infusion processes, Hexcel’s HexPly XF reduce shell manufacturing time by up to 2 hours and removes all surface defects prior to painting.

Read MoreBilsing expands aerospace composites capabilities with 3D tape laying equipment

Conbility PrePro 3D system will be used to produce components for aircraft interior galleys, seats and overhead bins.

Read More