The German Aerospace Center (DLR) is leading innovation in everything from space launch vehicles and aircraft, to digital technologies and nextgen mobility. In composites, it has advanced a wide range of technologies from thermoplastic composite welding and liquid resin infusion of primary aerostructures to Composites 4.0 intelligent production systems, to name just a few.

Now, DLR Institute of Composite Structures and Adaptive Systems (Braunschweig, Germany) is aiming to help industrialize 3D printing of continuous fiber composites by establishing a demand-oriented, industry-diversified, global platform for technology users and providers of Additive Extrusion called EmpowerAX.

DLR discussed EmpowerAX at ITHEC 2020, and I followed up with Xenia Stumpf and Maik Titze at DLR. Here, I share what I’ve learned.

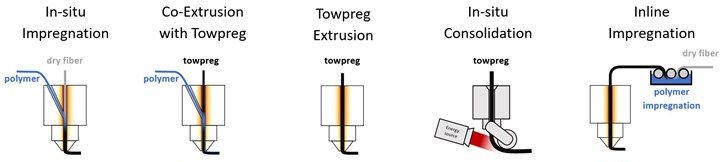

Concepts for direct fiber integration in composites 3D printing. Information source: Alexander Matschinski, Virtual Symposium on AFP and AM, TU Munich, Chair of Carbon Composites (LCC), Sep. 2020. Photo Credit: “3D printing with continuous fiber: A landscape”, CW Oct 2020.

Why additive extrusion?

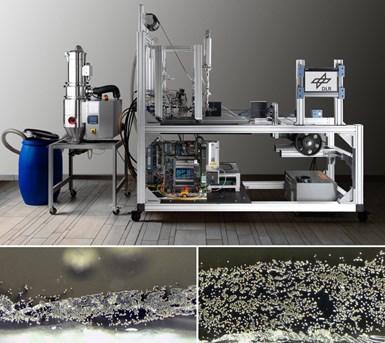

DLR has developed an impregnation technology for continuous fiber-reinforced thermoplastic 3D printing filaments that reduces production costs by up to 80%. Photo Credit: 3D-printed CFRP components – A new impregnation technology reduces costs.

“We are developing fiber impregnation technologies with thermoplastics for more industrial, cost-effective production,” explains Maik Titze, responsible for additive manufacturing at DLR Institute of Composite Structures and Adaptive Systems in Braunschweig. “This includes designing our own industrial print heads and developing methods for analysis and testing of materials and processes.” He notes that additive extrusion using continuous fibers offers not only increased strength and stiffness but also the possibility to integrate sensing and electrical functions. Additive extrusion combines thermoplastics and continuous fibers to create multifunctional structures that avoid high tooling costs, improve production efficiency and enable new designs.

“Additive manufacturing will not replace all conventional composite processes,” Titze concedes, “but it can be combined with processes such as automated fiber placement (AFP) or filament winding, for example, to provide novel solutions and value. Because we are only working with continuous fiber 3D printing, EmpowerAX is really focused, which will allow us to achieve a high level of results. But within additive extrusion, EmpowerAX is technology neutral. We won’t push any specific technologies.”

An Approach to Reduce Investment for Industry

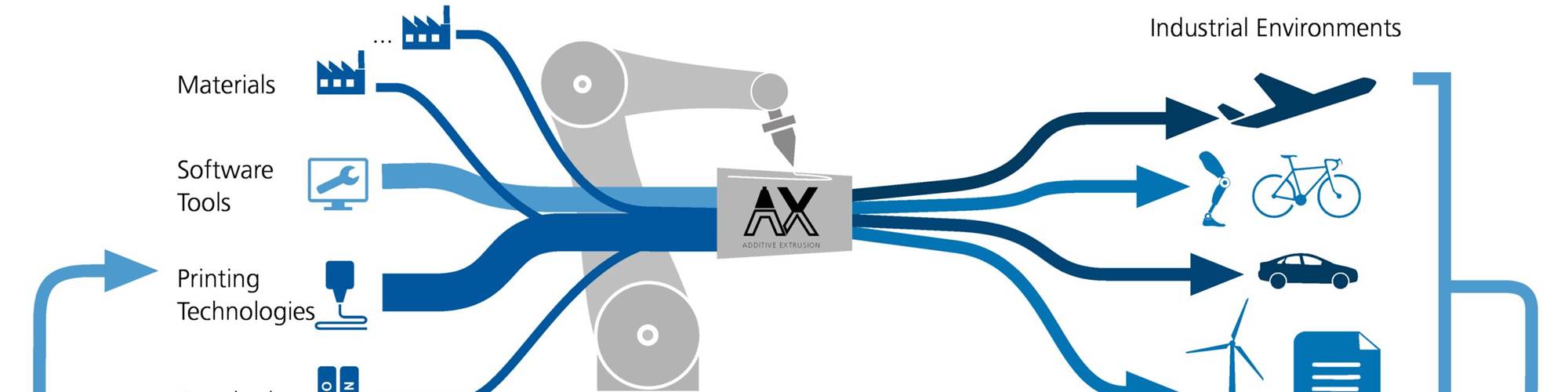

One of the goals of EmpowerAX is to connect additive extrusion technology providers and users in a way that helps each to identify which technologies best fit which applications, leading to faster successful adoptions and technology maturity. Photo Credit: DLR.

Global, diversified platform

“Right now, it’s hard to understand which of these technologies would be suitable for your application and what needs to be done to adapt it to your industrial environment and applications,” Titze continues. “Our goal is to look at the spectrum of what is available, including providers and users, and set up a diversified platform that spans market sectors, including aerospace, automotive, medical and industrial, for example. This platform, EmpowerAX, then gives the ability to do a neutral technology assessment, and we will work with industry to develop standardization and qualification measures to help increase the ease of using such technology. The idea is not to develop a new norm with tech providers and users, but to agree on how to do a technology assessment and which performance indicators to use.”

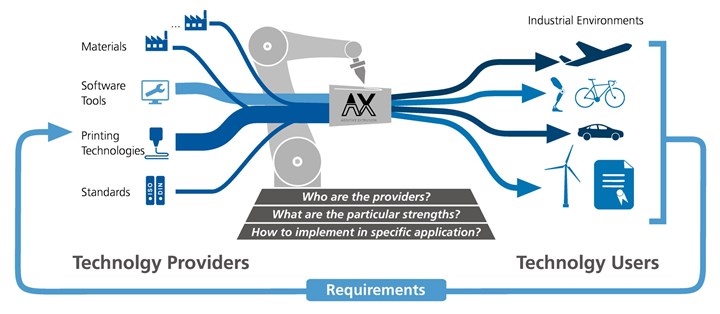

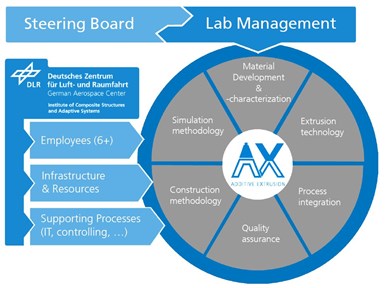

EmpowerAX Innovation Lab operational structure. Photo Credit: DLR.

EmpowerAX membership is voluntary and global. English is the language used for work. There are more than 30 members, currently, comprising technology providers and big technology users. “We are internally funded for up to 6 employees per year,” says Titze. “They will support the work needed to maintain this global platform. Our members have agreed to collaborate on the basis that we will not share information with the public but only with EmpowerAX members. Membership is currently free, but we are currently only accepting organizations already involved with additive extrusion of continuous fibers. After May 2021, we will open membership further.” The only other requirement, he notes, is that “you must be willing to share information and contribute. You cannot simply take. There is no passive membership.”

Technology screening stages

The idea, says Titze, is not only to transfer technology to industries already using composites, but also to use EmpowerAX as an enabler to enlarge the market and applications for composites. “For example,” he says, “in the medical industry, what special requirements must be met? What needs to be done to meet these? How can you ensure the quality you need and how can this be achieved for an industrial production environment?”

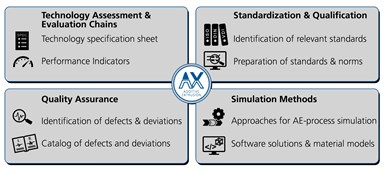

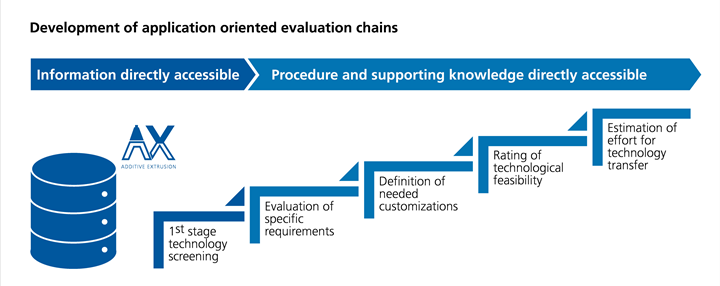

Development of application-oriented stages of evaluation to reduce time and cost for matching users to technology providers and vice versa. Photo Credit: DLR.

To answer these questions, EmpowerAX proposes a staged approach as shown in the diagram above. “The first stage is technology screening,” says Titze. “If you, as a possible user, want to see if a technology will work for your application then we look at things like geometrical limitations, production volumes and parts/function integration requirements, etc. We agree with all members on a preset list of roughly 15 parameters, such as specific strength and stiffness, and then pre-identify the suitability of the different technologies, depending on what your application requires. Therefore, we cooperate with materials/technology providers to obtain the standard parameter data and assess them in advance. We then work with datasheets from materials/technology providers to obtain the standard parameter data. So, for example, out of 10 solutions available, during this first stage, you can downselect to perhaps three, and then start evaluating data to compare these.”

Evaluating specific requirements is the next stage. For example, if this application is in rail or aircraft interiors, then parameters on fire, smoke and toxicity (FST) performance will be needed. “After this,” says Titze, “we will define if customizations are required to make each technology work for your application and determine the efforts required.”

The goal is to give a quantification of how the finalist technologies for a given application measure up in terms of technology feasibility and how much work/time/cost it will take to transfer the technology for industrial use. “After going through these stages of evaluation, it should be easy for you to understand which steps are required to make each technology possible for your application,” Titze explains. “For technology providers, this leads to faster technology transfer to new markets and reduces their investment and effort. It also identifies real business cases that are well-suited for their technology, where they have strengths.”

EmpowerAX example of the possible framework for standardization. Note that specific standards are given as suggestions. Photo Credit: DLR.

Standardization and qualification

Another key part of the EmpowerAX vision is to help mature additive extrusion technologies via standardization and qualification. “We studied already what standards are out there and which could work for these technologies, for example within ASTM, ISO and VDI (German government standards),” says Titze (see animated image above). “So, it is looking at standard tests, what works, what doesn’t and what modifications are needed. This is work that most companies would like to avoid because it is tedious, time-consuming and expensive. It is much better for the industry if everyone is not replicating these efforts. Thus, our aim is to help achieve faster standards for increased maturity, but with a wide set of inputs from industry and transparency to industry.”

“Also, if you combine a particular additive extrusion technology with other process steps, you will need to integrate it and implement quality assurance standards,” Titze points out. “This includes nondestructive testing (NDT), sensors and software. We’ve already started by compiling a catalog of possible defects and process deviations. How can you avoid and detect these? What can you do to remediate should they occur? We can then begin to assemble a database of possible NDT and process monitoring options.”

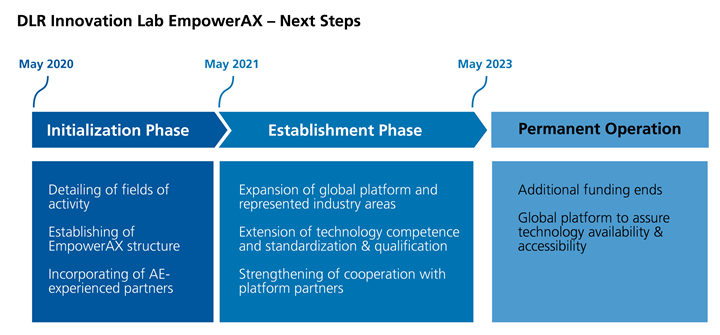

Timeline for EmpowerAX

“Our first goal is to provide a framework for what is industrially available today,” says Titze. “We are not trying to further open the spectrum of systems just yet, but instead want to show what is there and how these technologies can be used. We believe some improvements will come just through systematic testing and evaluation. We also see benefits from being able to display what is possible with current technologies. In addition, by identifying obstacles, we can have a discussion of how to overcome these, which provide further improvements and maturing of the technologies.”

“We see additive extrusion as a potentially easier path for companies new to composites versus using processes involving autoclaves or resin infusion,” notes Titze. “We also see it as well-tuned for more industrial outcomes. EmpowerAX is also about looking at industrial applications and addressing the obstacles that have prevented the use of additive extrusion composites to date. For example, current shortcomings include process repeatability and stability. The technology has been pushed to market relatively quickly, so there are areas which are not yet at a maturity level to be used widely. So, that is what we’re doing. We aim to show what can be done and what needs to be done and then work collaboratively to complete that work, advancing both the technologies as well as successful end uses in industry.”

More information can be found at www.empowerax.dlr.de

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More