Processes

Fortify secures $20 million funding to advance 3D printing composites

Funds will be used to scale up manufacturing, the team and materials development programs.

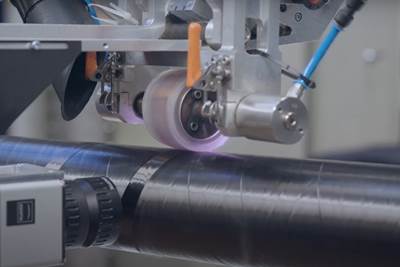

Read MoreHeraeus, University of Sheffield AMRC partner to develop innovative composite technologies

Tier 2 membership enables Heraeus Noblelight to explore filament winding capabilities using its humm3 technology for rapid layup of thermosets, dry fiber and thermoplastics.

Read MoreSaint-Gobain invests in Continuous Composites for CF3D commercialization

Strategic investment is an initiative of NOVA, Saint-Gobain’s venture arm, to pursue Continuous Fiber 3D Printing growth.

Read MoreImpact tests on RAMSSES ship hull demonstrator show resilience of composites

Damen Shipbuilding and project consortium partners test 6-meter-high, resin-infused composite hull section.

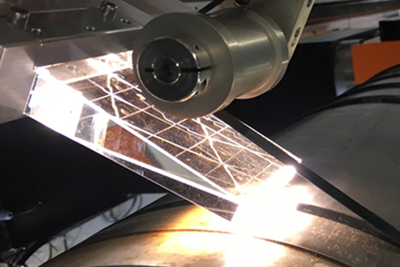

WatchChallenges of laser-assisted tape winding of thermoplastic composites

Practical solutions for process-related challenges in LATW, which has great potential for pressure vessels and storage tanks.

WatchThermwood advances LSAM capabilities with automatic print temperature monitoring

Thermal Sensor Layer Automation system uses a non-contact temperature sensor for continuous temperature data, ensuring precise fusion between large-scale thermoplastic printed layers.

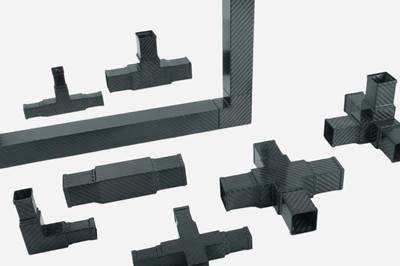

Read MoreRefitech expands RefiFLEX range, supplies pultrusion profiles for construction solutions

High-precision carbon fiber square tubes and CarboSix UD carbon fiber pultrusion profiles meet demand for lighter, stiffer, more high-performance systems.

Read MoreFrance Relance award granted to Omega Systèmes for automated composite slitting solutions

Central to the OMEGA-WEB 2022 will be inline automated inspection, and large-scale production of composite parts via AFP, ATL to accelerate the aerospace sector.

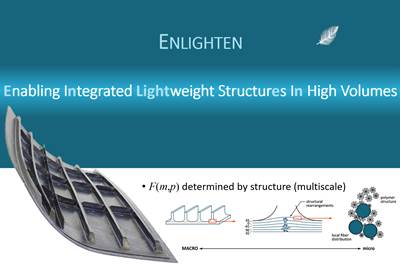

Read MoreENLIGHTEN program launched to speed thermoplastic composites industrialization

Multi-scale modeling, testing, sensors and machine learning will advance understanding and algorithms to achieve process control and optimization for both aerospace and automotive supply chains.

WatchTeton SmartSlice 2.0 offers improved functionalities

Simulation tool for 3D printing provides more ergonomic user features, including view displacement options, tooltips and 10 new material options.

Read More

.jpg;maxWidth=300;quality=90)