Reinforcements

Innovative tooling, automation enable new line of composite window wells

Moldmaker and automation specialist Commercial Tool Group provided RockWell with custom compression molds and robotics to enable high-volume, low-cost production.

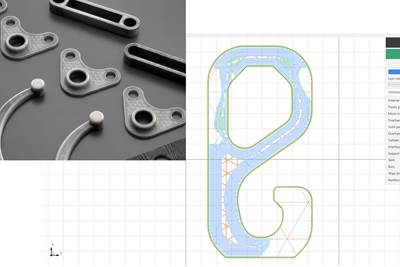

Read MoreAnisoprint launches Aura 2.1 slicing software for continuous fiber 3D printing

New features include “masks” giving users greater control over fiber reinforcement in an easy-to-visualize manner.

Read MoreCarbon Axis XCell strengthens AFP capabilities at Compositadour

New robotic cell will expand testing, prototyping and pre-series production for industries looking to automate composites preforming.

WatchNCC proposes natural fiber use for SME subterranean transport network

Under an NCC SME Boost program, research indicates composite reinforcements will reduce material, manufacturing costs and prove more sustainable for innovative SME project.

Read MoreAnalySwift and University of Central Florida work with NASA to develop thin-ply composites

Materials will be characterized and performance modeled for wide array of aircraft and space applications.

Read MoreDLR launches EmpowerAX to industrialize continuous fiber 3D printing

Global, industry-diversified platform will increase access to additive extrusion (AX) technologies and accelerate technology transfer for users and providers.

Read MoreStratasys carbon fiber material for 3D printer line is more functional, lightweight and versatile

ABS-based carbon fiber material for the Stratasys F123 Series 3D printer line is 15% stronger and 50% stiffer compared to standard ABS.

Read MoreSolvay, Vertical Aerospace expand on UAM agreement

Composite materials supplier Solvay Composite Materials and urban air mobility (UAM) manufacturer Vertical Aerospace offer details about materials, process use in VA-1X aircraft.

Read MoreMcLaren Artura features new composite architecture

The Artura is a plug-in hybrid that uses the new McLaren Carbon Lightweight Architecture.

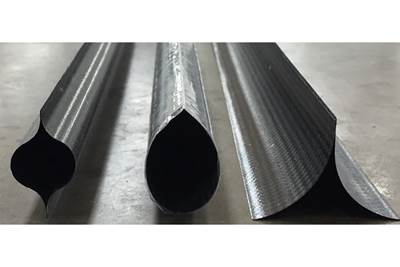

Read MoreHot drape forming

Heat, vacuum and/or pressure advance from debulking prepreg layups to automated preforming of dry reinforcements for faster composites production.

Read More